14

YASKAWA

TOEP C730600 74D LED Keypad Installation Manual

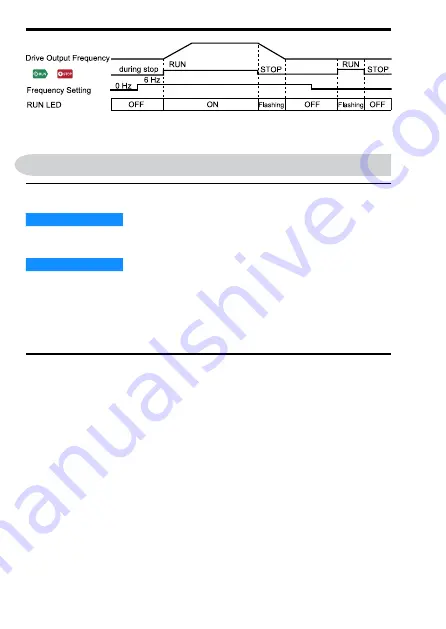

Figure 4.3 Relation between RUN LED and Drive Operation

5

Installation Procedure

◆

Section Safety

NOTICE

Damage to Equipment. Correctly connect all pins and

connectors. If the pins and connectors are incorrect, it can cause damage to

equipment and incorrect operation.

NOTICE

Damage to Equipment. Do not bend the communication

cables more than the bend radius specifications. If you bend the cables too

much, it can break the wires and loosen connections.

Note:

Use Yaskawa connection cables or recommended cables only. Incorrect cables can

cause the drive or option to function incorrectly.

◆

Remote Operation

You can remove the digital operator and use a 3 m (9.8 ft.) length

maximum extension cable to connect it to the drive. The option

makes it easier to operate the drive when you install the drive in a

location where you cannot easily access it. Contact Yaskawa or

your nearest sales representative to order optional accessories.

/