YASKAWA

TOEPC710616134G AC Drive L1000A Technical Manual Addendum

41

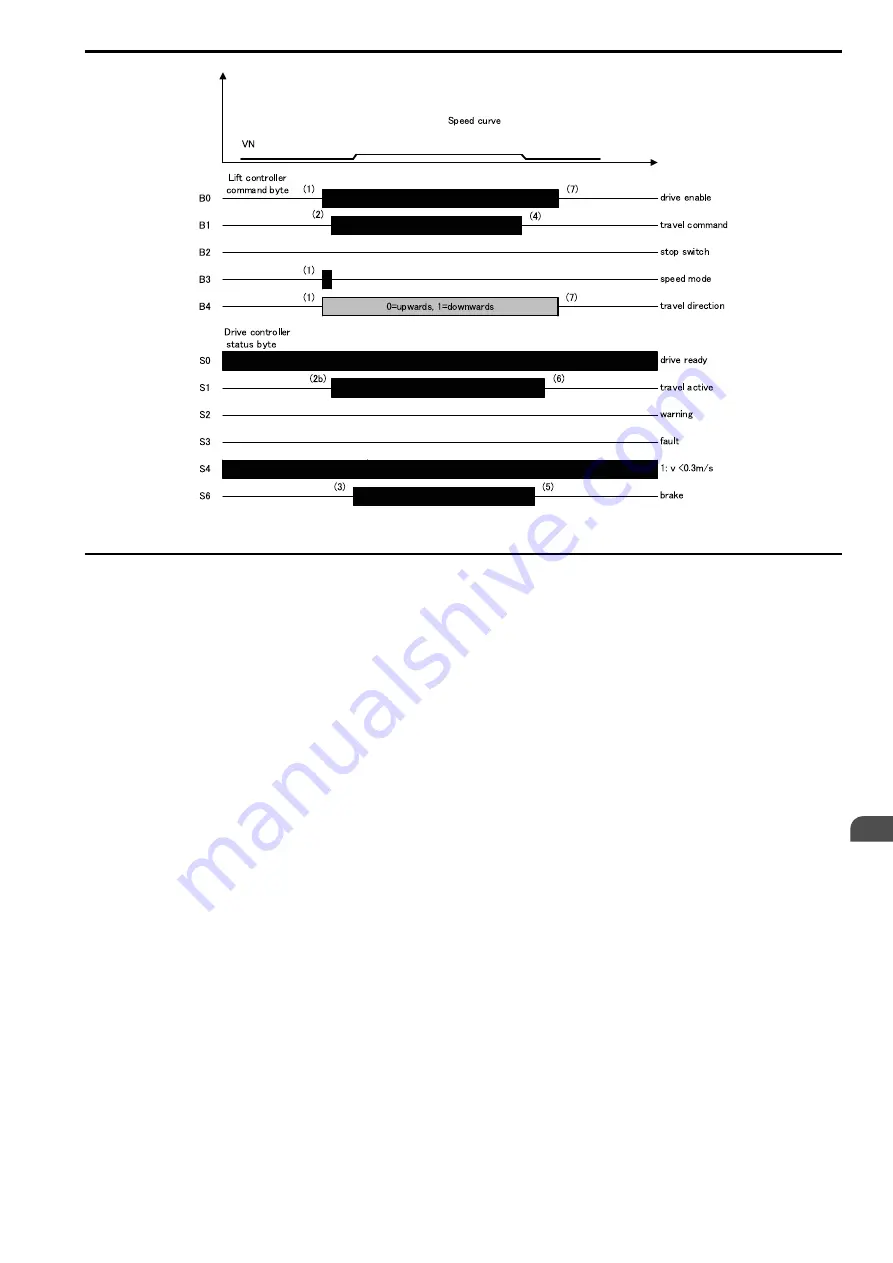

Figure 6.8 Re-leveling Travel with Electric Stop

◆

DCP3: Lift Controller without Absolute Sensor System

■

Travels at V4 followed by Constant Deceleration Distance SV4

Long Travel at High Lift Speed V4 :

1. Before the travel starts, the speed mode "Fast [bit G7]" (V4) is transmitted.

2. The travel starts with activation of travel command bit B1.

3. After the travel command has been switched off, the drive decelerates to crawl speed within the fixed distance

SV4. The distance is supplied by the motor's incremental encoder. Stop switch bit B2 must be activated not

later than at this point in time.

4. The lift controller positions the lift car with the stop switch bit B2.

5. The lift controller switches the travel contactors off when the drive controller ends the travel at S1 = 0.

EN

Summary of Contents for L1000A CIMR-LC F Series

Page 1: ...AC Drive L1000A For Lift Applications Technical Manual Addendum Type CIMR LCxFxxxxxxx 913x Web...

Page 98: ...15 Appendix 98 YASKAWA TOEPC710616134G AC Drive L1000A Technical Manual Addendum...

Page 99: ...15 Appendix YASKAWA TOEPC710616134G AC Drive L1000A Technical Manual Addendum 99 EN...

Page 100: ...15 Appendix 100 YASKAWA TOEPC710616134G AC Drive L1000A Technical Manual Addendum...

Page 101: ...15 Appendix YASKAWA TOEPC710616134G AC Drive L1000A Technical Manual Addendum 101 EN...

Page 102: ...15 Appendix 102 YASKAWA TOEPC710616134G AC Drive L1000A Technical Manual Addendum...