6-3

6

Before Reading this Chapter

This chapter describes the use of each CN1 I/O signal for the SGDH SERVOPACK with the

NS115. It also describes the procedure for setting the related parameters for the intended

purposes.

The following sections can be used as references for this chapter.

• CN1 I/O signal list: Refer to

3.3.3 I/O Signal Names and Functions

.

• CN1 I/O signal terminal layout:

3.3.2 I/O Signals Connector (CN1) Terminal Layout

.

• Parameter list: Refer to

Appendix B List of Parameters

.

The CN1 connector is used to exchange signals with external circuits.

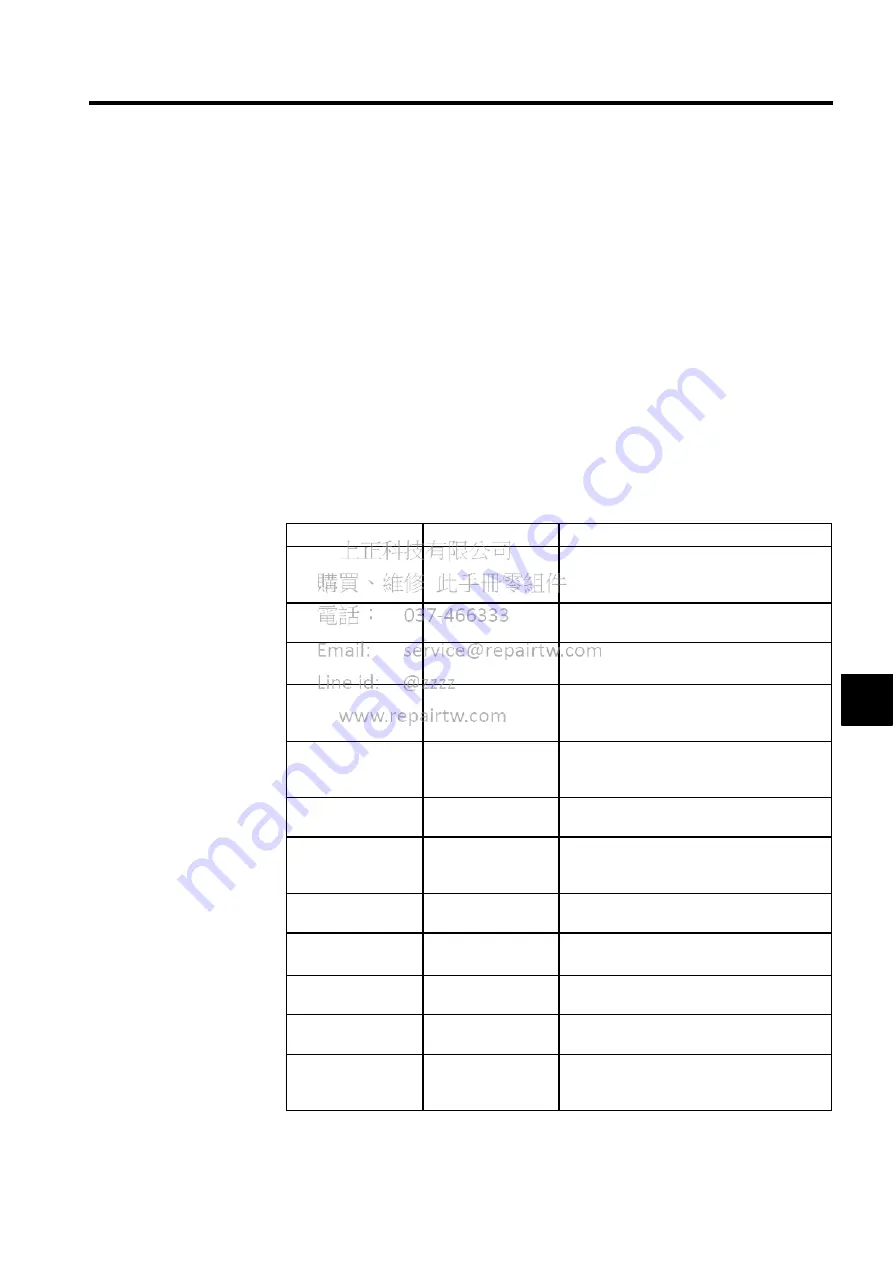

Parameter Configurations

Parameters are comprised of the types shown in the following table. Refer to

Appendix B

List of Parameters

.

Type

Parameter No.

Description

Function Selection

Parameters

Pn000 to Pn005

Select basic and application functions such as

the type of function or the stop mode used when

an alarm occurs.

Servo Gain and

Other Parameters

Pn100 to Pn123

Set numerical values such as speed and position

loop gains.

Position Parameters Pn200 to Pn208,

Pn804 to Pn808

Set position parameters such as the reference

pulse input form and electric gear ratio.

Speed Parameters

Pn300 to Pn308

Set speed parameters such as speed reference

input gain and soft start acceleration/decelera-

tion time.

Torque Parameters

Pn400 to Pn409

Set torque parameters such as the torque refer-

ence input gain and forward/reverse torque lim-

its.

Acceleration/Decel-

eration Parameters

Pn80A to Pn812

Set acceleration/deceleration parameters, such

as selecting an acceleration/deceleration filter.

Sequence Parame-

ters

Pn500 to Pn512,

Pn801 to Pn803

Set output conditions for all sequence signals

and changes I/O signal selections and alloca-

tions.

Motion Parameters

Pn814 to Pn819

Set motion parameters, such as the zero point

return direction.

MECHATROLINK-

II

Parameters

Pn800 to Pn802,

Pn813, Pn816

Set parameters for MECHATROLINK-II com-

munications settings.

Others

Pn600 to Pn601

Specify the capacity for an external regenerative

resistor and reserved parameters.

Auxiliary Function

Execution

Fn000 to Fn013

Execute auxiliary functions such as JOG Mode

operation.

Monitor Modes

Un000 to Un00D

Enable speed and torque reference monitoring,

as well as monitoring to check whether I/O sig-

nals are ON or OFF.