4 Installation

4.5 MotoMount Installation

4-22

162068-1CD

162068-1CD

MH-SERIES

POSITIONER

4.5

MotoMount Installation

The MotoMount drive components are usually delivered assembled to the

drive assembly (MH95, MH185, or MH505). However, if retrofitting

MotoMount on a system already installed in the plant, follow these

instructions:

4.5.1

Preparation

Successful installation requires the MotoMount drive components be

firmly mounted to the headstock faceplate. Before installation, ensure the

faceplate is clean and is not warped or deformed.

4.5.2

Unpack and Assemble

The MotoMount system will be shipped in a box with the following

components (unless it is part of a larger system):

• MotoMount drive components

• Dowel pins (2)

• Mounting hardware

• Weld ground cable

Carefully remove plastic wrapping from components and inspect them for

shipping damage.

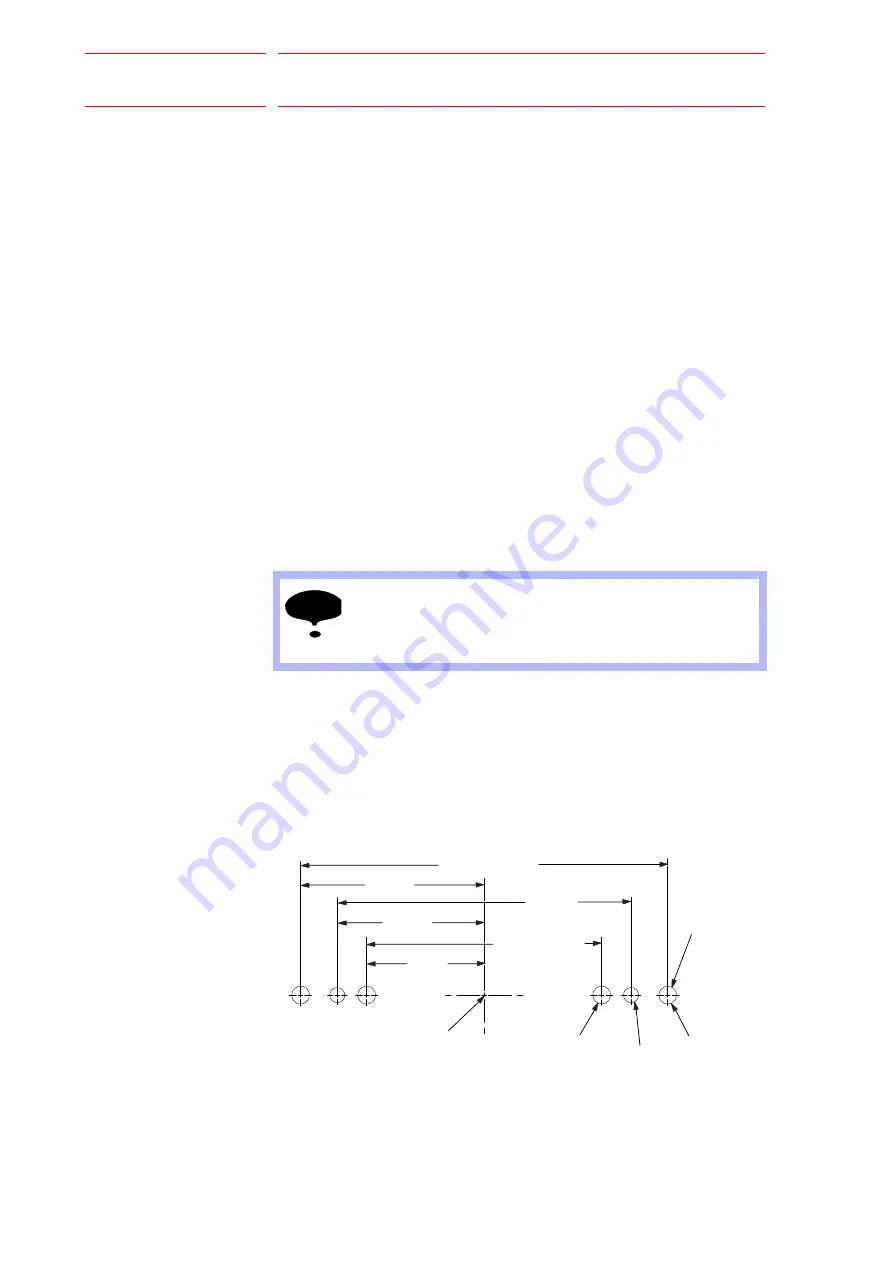

4.5.2.1

Installing Fixture Dowel Pins

The dowel pins must be installed into the back of the mounting block

before the assembly is mounted onto the faceplate. There are four holes

in the back of the mounting block. See

to determine which

holes to use for your application. If your headstock faceplate does not

have the matching dowel holes, it must be modified per the following

template.

Fig. 4-31: MotoMount Mounting Hole Pattern

NOTE

Notify shipping contractor if there is any shipping damage.

M12 X 1.75

MH95/185 DOWEL

POSITION

250.00 MM +/- 0.015

125 MM

CENTER OF

ROTATION

DIA. 12.00 THRU

FOR DOWEL

200 MM

80 MM

100.0 MM

160.00 MM +/- 0.015

48/101