4-27

162068-1CD

162068-1CD

MH-SERIES

POSITIONER

4 Installation

4.7 Conducting a Safety/Operation Check

4.6.4

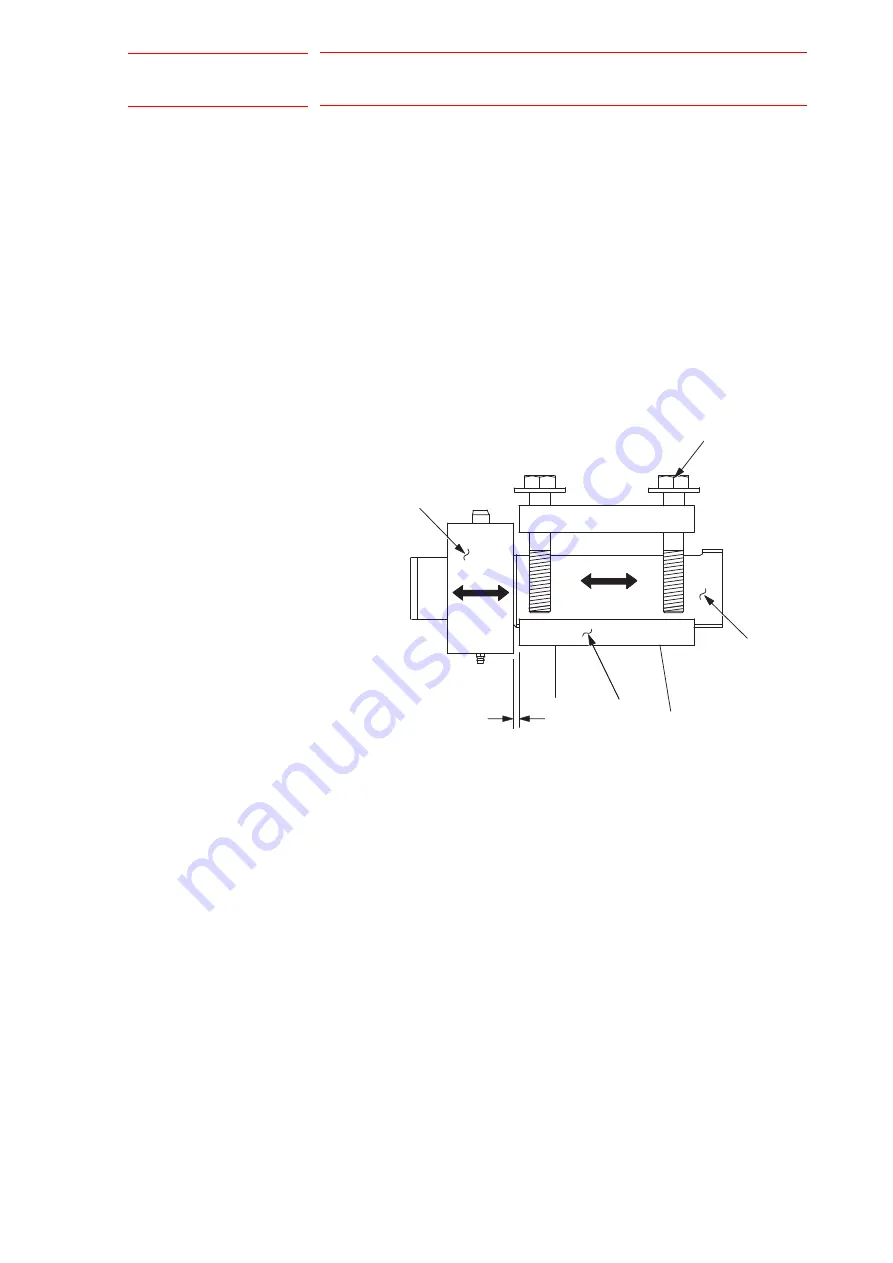

Variable Tooling Size Accommodations

The MotoMount system can adapt to small variations in tooling fixture

lengths without changing the tailstock’s performance or permanent

location. Two steps can be taken to adjust the tooling fixture distance.

4.6.4.1

Changing Adapter Shaft Position

The preferred way change the adapter shaft position is to simply slide the

tailstock adapter either way along the adapter shaft. If more adjustment is

needed, loosen the four tailstock bolts and slide the adapter shaft and the

tailstock adapter until a suitable position is acquired. These two processes

do not effect MotoMount’s performance. It is important that a minimum

distance is maintained between the tailstock adapter and the top of the

tailstock column.

Fig. 4-36: Adapter Shaft Position

4.6.4.2

Reinstalling the Adapter Shaft

Once the new position for the adapter shaft is found, torque the tailstock

bolts to 350 N•m (259 lbf-ft.).

4.7

Conducting a Safety/Operation Check

Before operating either MH-Series SIGMA-5 Positioner take a few

minutes to perform a safety/operation check. To perform a safety/

operation check, proceed as follows:

1. Check that all cable connections are tight.

2. Verify the headstock and tailstock are level and parallel.

12.7 MM MINIMUM

DISTANCE

ADAPTER

SHAFT

TAILSTOCK

ADAPTOR

TAILSTOCK

BOLT

TAILSTOCK

COLUMN

TOP

53/101