6-11

162068-1CD

162068-1CD

MH-SERIES

POSITIONER

6 Maintenance

6.6 Maintenance Schedule

6.6

Maintenance Schedule

6.6.1

MH-Series SIGMA-5 Positioner

See Table 6-2: for the periodic maintenance schedule.

6.6.2

MotoMount

See Table 6-3: for periodic maintenance procedures.

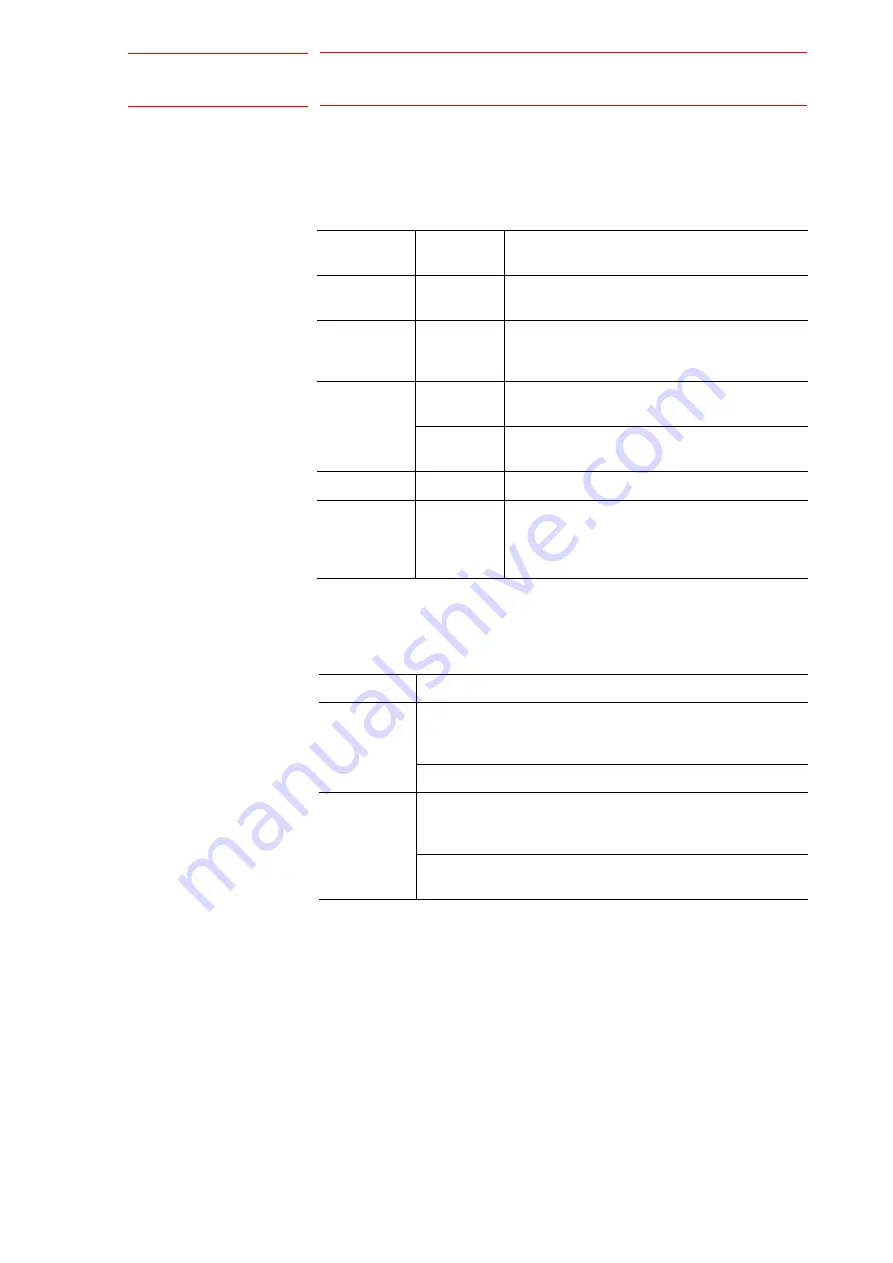

Table 6-2: Maintenance Schedule

Inspection

Item

Frequency

Inspection Operation

Physical

damage

Daily

Check for physical damage; this indicates a

load collision and is evidence of misuse.

Excessive or

unusual

noise

Daily

Listen for grinding, excessive or irregular noise.

Contact Yaskawa Motoman Service Department

at (937) 847-3200.

Weld

Brushes

First Week

Check for dirt and ensure full contact with

faceplate.

Weekly

Check for dirt and ensure full contact with

faceplate.

Cleaning

As required

Clean with dry cloth or compressed air.

Lubrication Every

20,000

hours or 5

years

Flush and relubricate using Moly white grease.

Table 6-3: Periodic Maintenance

Frequency

Procedure

Daily

Using compressed air or a suitable brush, remove any weld

spatter and dirt from the drive components with particular

attention to the drive bushing area.

Verify tooling bolts are tight.

Monthly

Provide 2-3 pumps of grease (Motoman, Inc. 133174-2, Kluber

#039067, Lubriplate 3000, or equivalent) to the main bearing

zerk fitting.

Verify the leveling and lag bolts are tight on the headstock/

tailstock columns

73/101