6

Disassembly and Reassembly of the Speed Reducer

6.3

Disassembly and Reassembly of the U-Axis Speed Reducer

6-8

HW1484673

HW1484673

6.3

Disassembly and Reassembly of the U-Axis Speed

Reducer

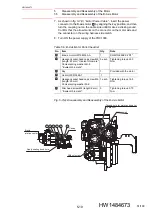

• Refer to

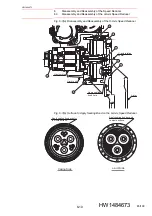

fig. 6-3(a) “Disassembly and Reassembly of the U-Axis

Disassembly

1. Turn OFF the power supply of the YRC1000.

2. Disconnect the internal wire harness in the top of the U-arm.

(Refer to

.)

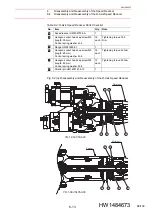

3. In order to prevent the U-arm unit from falling, the U-arm unit must be

supported by using a chain block, etc. before separating the L-arm and

U-arm unit.

4. Unscrew hexagon socket head cap screws

and

, and then lower

the U-arm unit.

5. Remove the U-axis motor

, and then remove the input gear

.

(Refer to

chapter 5.3 “Disassembly and Reassembly of the U-Axis

If the speed reducer

is removed without removing the U-axis motor,

an external force will be applied to the shaft of the motor, causing the

shaft to bend or causing damage to the motor.

6. Unscrew the hexagon socket head cap screws

, and then remove

the speed reducer

and O-ring

.

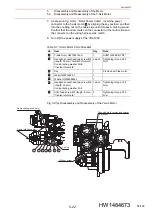

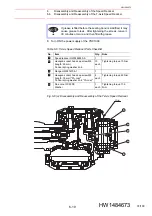

Reassembly

1. Mount the O-ring

on the speed reducer

.

2. Apply ThreeBond 1206C to the contact surface of the speed reducer

and the U-arm unit, and then mount the speed reducer

on the U-

arm unit. For the place to apply sealing bond, refer to

“Surface to Apply Sealing Bond on the U-Axis Speed Reducer”

. At

this time, be careful so that the O-ring

does not come off.

3. Tighten the hexagon socket head cap screws

with the tightening

torque shown in

table 6-3 “U-Axis Speed Reducer Parts Checklist”

.

4. Reassemble and mount the U-axis motor.

(Refer to

chapter 5.3 “Disassembly and Reassembly of the U-Axis

(When replacing the speed reducer, replace the input gear, too.)

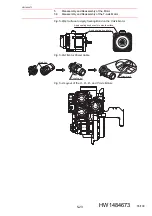

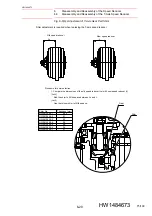

5. Apply ThreeBond 1206C to the contact surface of the speed reducer

and the L-arm, and then mount the U-arm unit with the mounted speed

reducer

on the L-arm. For the place to apply sealing bond, refer to

and

fig. 6-3(c) “Surface to Apply Sealing Bond on the L-Arm

on the Other Side of the U-Axis Speed Reducer”

.

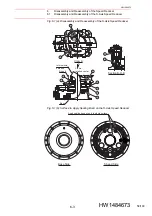

6. Tighten the hexagon socket head cap screws

with the tightening

torque shown in

.

7. Tighten the hexagon socket head cap screws

with the tightening

torque shown in

.

8. Mount the internal wiring harness.

(Refer to

.)

2

3

6

7

1

4

1

5

5

1

1

1

15

4

1

2

3

63/109