3.2 Mounting Procedures for Manipulator Base

3-3

3.2.1

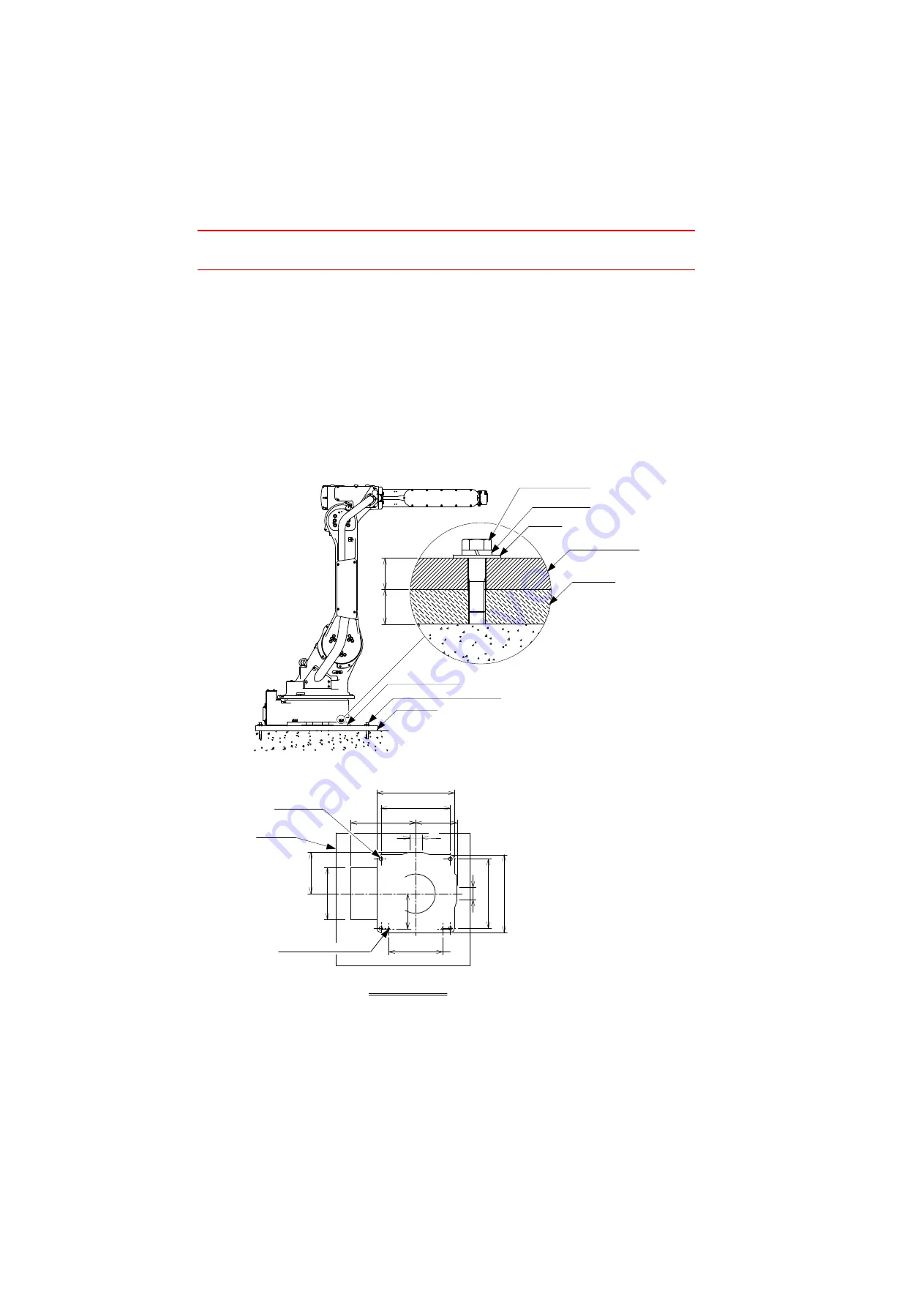

Installation Example

For the first process, anchor the baseplate firmly on the floor. The baseplate should have

enough rigidity, which is 32 mm or more in thickness. The size of the anchor bolt recom-

mended for the baseplate fixation is M16 or larger.

Next, fix the manipulator base to the baseplate. There are 4 mounting holes on the manipula-

tor base: securely fix the manipulator to the baseplate using 4 hexagon head screws M16 (60

mm long is recommended). Tighten the hexagon head screws and anchor bolts firmly so that

they will not be loosened during the operation. See "Fig. 4 Manipulator Installation Example"

for the method.

Fig. 4 Manipulator Installation Example

Baseplate

Spring washer

Bolt M16 (4 bolts)

Washer

Manipulator base

Baseplate

40 mm

or more

25

Manipulator base

Anchor bolt (M16 or larger)

Baseplate

18 dia. holes

(4 holes)

Manipulator Base

+0.018

0

12 dia. holes (2 holes)

375

60

335

±

0.1

200

313

375

335

±

0.1

170

±

0.1

260

60

250

±

0.1

200