9.2 Notes on Maintenance Procedures

9-9

9.2.3

Grease Replenishment/Exchange for L-axis Speed

Reducer

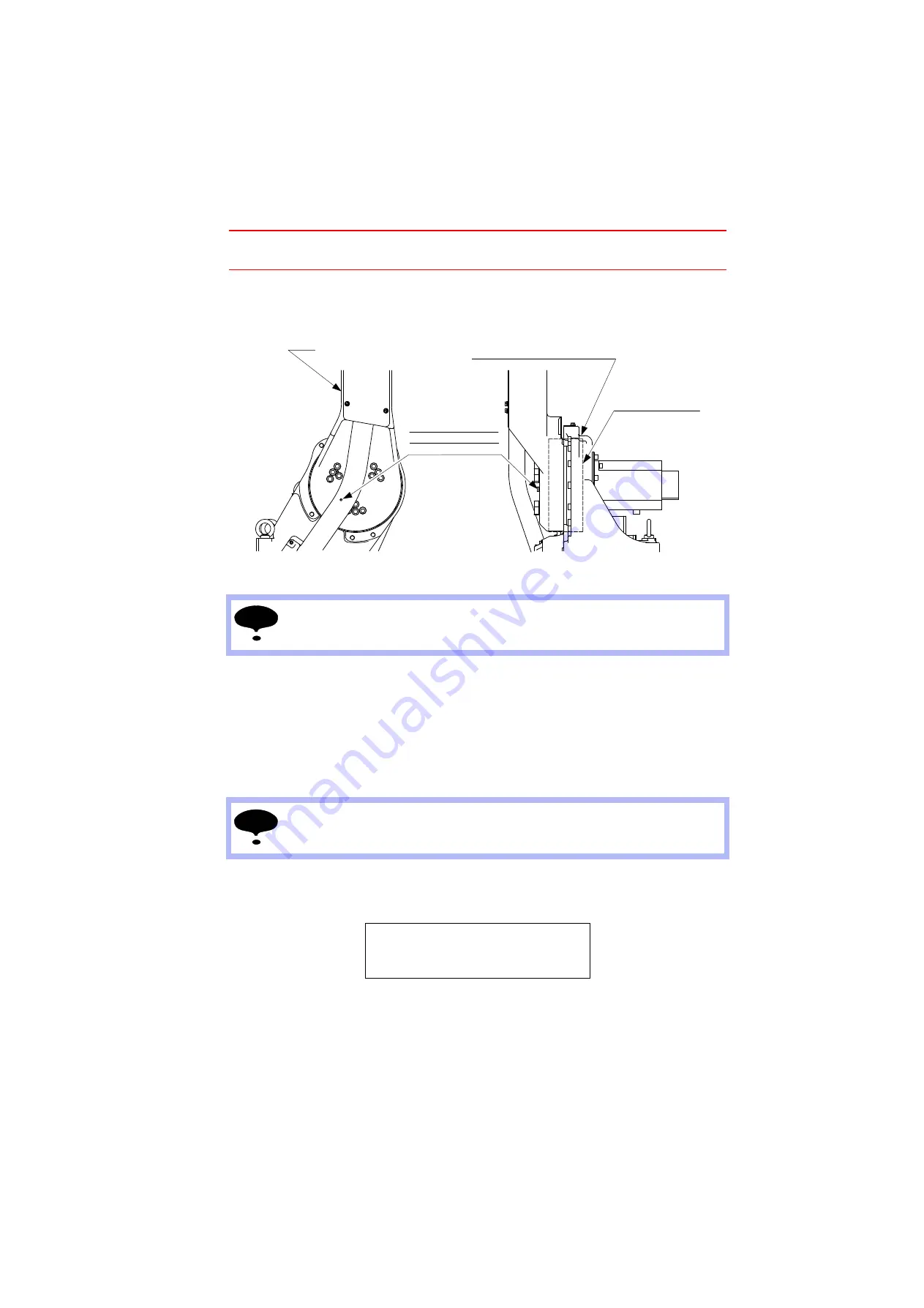

Fig. 25 L-axis Speed Reducer Diagram

Grease Replenishment

(Refer to "Fig. 25 L-axis Speed Reducer Diagram".)

Replenish the grease in accordance with the following procedure:

1. Posture the L-axis vertical to the ground.

2. Remove the plug and the screw from grease exhaust port and grease inlet respec-

tively.

3. Install the grease zerk A-MT6X1 on the grease inlet. (The grease zerk A-MT6X1 is

delivered with the manipulator.)

4. Inject the grease into the grease inlet using a grease gun.

5. Move the L-axis for a few minutes to discharge the excess grease.

6. Remove the grease zerk and reinstall the hexagon socket head cap screw M6 on the

grease inlet. Tighten the screw with a tightening torque of 5 N·m (0.51 kgf·m). Apply

Three Bond 1206C on the thread part of the screw.

The exhaust port and the grease inlet are inverted in case of ceiling installation.

If grease is injected with the plug on, the grease will go inside the motor and may damage

it. Never fail to remove the plug before the grease injection.

Grease type: Molywhite RE No.00

Amount of grease: 30 cc

(60 cc for the 1st supply)

L-axis speed reducer

(Hexagon socket head plug PT1/8)

Grease inlet

(Hexagon socket head

cap screw M6)

Grease exhaust port

L-arm

NOTE

NOTE