9.2 Notes on Maintenance Procedures

9-14

9.2.6

Grease Replenishment for B-, T-axes Speed

Reducers

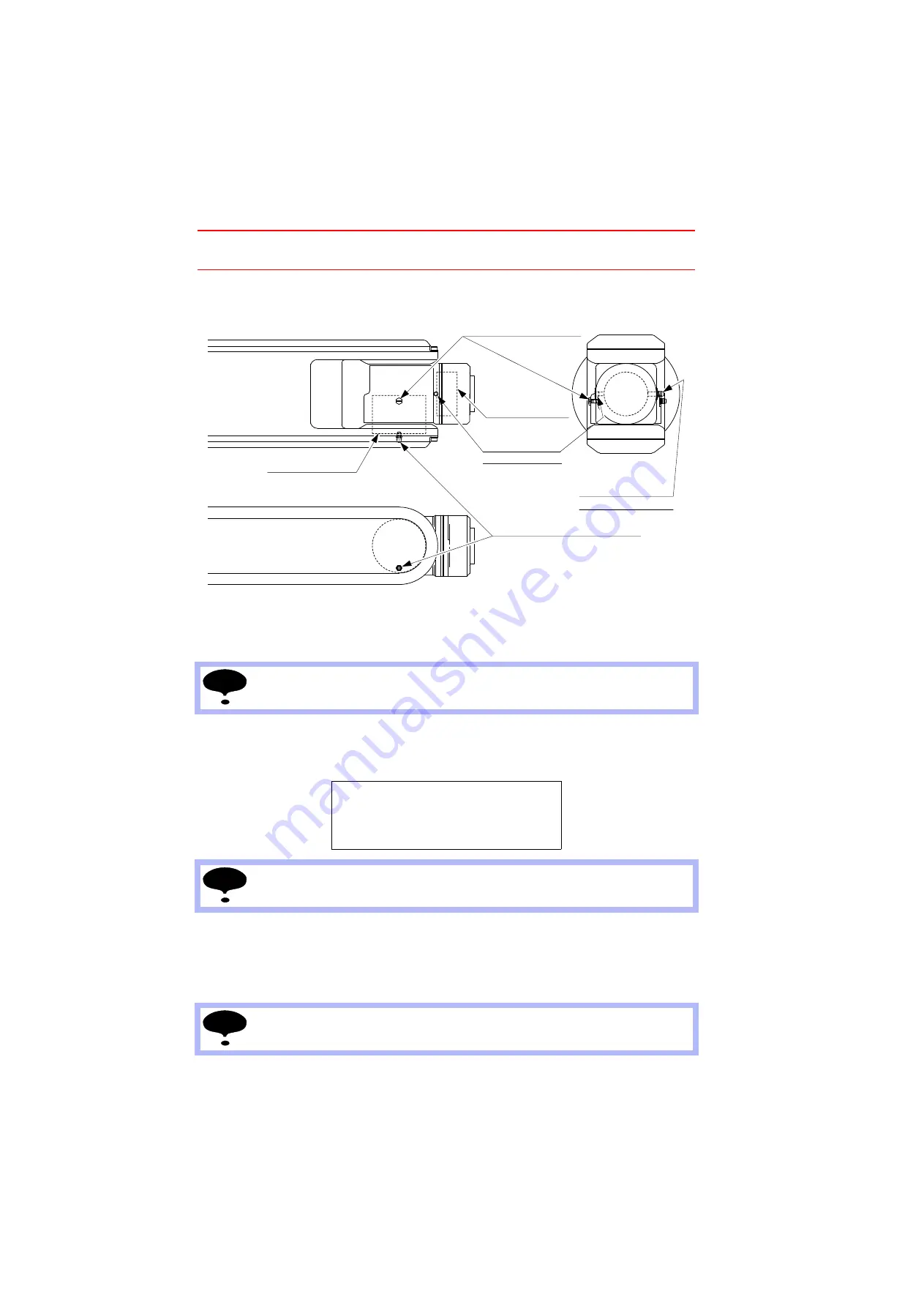

Fig. 28 B-, T-axes Speed Reducers Diagram

1. Remove the plug on the exhaust port for B-axis or the hexagon socket set screw on the

exhaust port for T-axis.

2. Remove the hexagon socket head cap screw on the grease inlet and install the grease

zerk A-MT6X1.

3. Inject the grease into the grease inlet using a grease gun.

4. Reinstall the plug on the exhaust port for B-axis or the hexagon socket set screw on

the exhaust port for T-axis. Apply Three Bond 1206C on the thread parts.

5. Remove the grease zerk on the grease inlet and reinstall the hexagon socket head cap

screw. Tighten the screw with a tightening torque of 5 N·m (0.51 kgf·m). Apply Three

Bond 1206C on the thread part.

Remove the cover for the B-axis speed reducer.

Grease type: Harmonic grease SK-1A

Amount of grease:

For B-axis: 10 cc (20 cc for the 1st supply)

For T-axis: 5 cc (10 cc for the 1st supply)

The exhaust port is used for air flow. Do not inject excessive grease into the grease inlet.

Mount the cover for the B-axis speed reducer. (Refer to " 9.2.9 Notes for Maintenance.")

B-axis speed reducer

T-axis speed reducer

Gease inlet (for B-axis)

Gease inlet (for T-axis)

(Hexagon socket

set screw M6)

Exhaust port (for T-axis)

Exhaust port (for B-axis)

(Plug LP-M5)

(Hexagon socket head

cap screw M6)

(Hexagon socket head cap screw M6)

NOTE

NOTE

NOTE