4-5

159281-1CD

HW1480357

HP20D

4 Grease Replenishment and Exchange

4.3 Grease Replenishment and Exchange for L-Axis Speed Reducer

4.3.2 Grease Exchange

.)

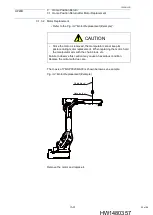

1. Make the L-arm vertical to the ground.

2. Remove the hexagon socket head cap screw from the grease inlet and

the hexagon socket head plug from the grease exhaust port.

3. Install the grease zerk A-MT6 x 1 to the grease inlet.

(The grease zerk is delivered with the manipulator.)

4. Inject grease through the grease inlet using a grease gun.

– Grease type:

VIGO Grease No.0

– Amount of grease:

approx. 500 cc

– Air supply pressure of grease pump: 0.3 MPa or less

– Grease injection rate:

8 g/s or less

5. The grease exchange is completed when new grease appears in the

exhaust port. (The new grease can be distinguished from the old

grease by color.)

6. Move the L-axis for a few minutes to discharge excess grease.

7. Remove the grease zerk from the grease inlet and reinstall the screw.

Apply ThreeBond 1206C to the thread part of the screw, and tighten

the screw with a tightening torque of 5 N•m (0.51 kgf•m).

8. Wipe the discharged grease with a cloth, and reinstall the plug on the

grease exhaust port. Apply ThreeBond 1206C to the thread part of the

plug, and tighten the plug with a tightening torque of 5 N•m

(0.51 kgf•m).

NOTE

If grease is injected with the plug on, grease will leak inside

the motor and may cause a damage. Make sure to remove

the plug before grease injection.

31 of 96