6-12

159281-1CD

HW1480357

HP20D

6 Disassembly and Reassembly of Speed Reducer

6.6 Disassembly and Reassembly of T-Axis Speed Reducer

6.6 Disassembly and Reassembly of T-Axis Speed Reducer

6 “Disassembly and Reassembly of T-Axis Speed

.

Disassembly

1. Turn OFF the DX100 power supply.

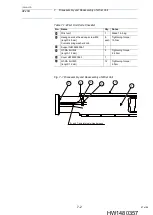

2. Remove the GT-SA bolts , then remove the right side part from the

point “A” in

6 “Disassembly and Reassembly of T-Axis

.

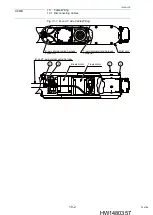

3. Remove the circular spline from the flange.

4. Remove the GT-SA bolts , then, remove the flex spline .

5. Remove the GT-SA bolts . Then, remove the housing from the

wrist base.

6. Remove the hexagon socket head cap screw , and remove the

gear and the shim . Then, pull out the wave generator .

Reassembly

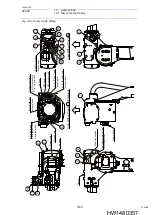

1. Apply Harmonic Grease SK-1A to the bearing of the wave

generator . Then, insert the wave generator in the housing .

2. Mount the shim and the gear .

3. Apply Loctite 242 to the thread part of the hexagon socket head cap

screw . Then, tighten it with the tightening torque shown in

"T-Axis Speed Reducer Parts Checklist"

4. Mount the housing (the assembly prepared in the steps 1 to 3

above) on the wrist base.

5. Temporarily tighten the GT-SA bolts .

6. Check if the backlash is proper, and adjust the shim as follows when

necessary: Remove the GT-SA bolt , then remove the housing .

Adjust the backlash by inserting the shim(s) on the list below between

the gear and the wave generator . Set the backlash to 0.05 to 0.1

mm on the gear’s pitch circle diameter of 52.5 mm.

7. Confirm the backlash is correct. Then, remove the GT-SA bolts

again, and remove the housing . Apply Harmonic Grease SK-1A on

the teeth of the gear .

8. Apply ThreeBond 1206C on the matching surface between the

housing and the wrist base. Then, mount the housing on the wrist

base. Tighten the GT-SA bolts with the tightening torque shown in

6 "T-Axis Speed Reducer Parts Checklist"

.

9. Mount the flex spline on the flange.

10. Tighten the GT-SA bolts with the tightening torque shown in

6 "T-Axis Speed Reducer Parts Checklist"

.

10

2

4

1

5

6

8

7

9

3

Shim Type

Thickness (mm)

SP012010

0.1

SP012015

0.15

SP012020

0.2

SP012050

0.5

3

3

6

9

7

8

6

5

5

6

7

3

5

6

7

6

6

5

1

4

63 of 96