vi

HW0481893

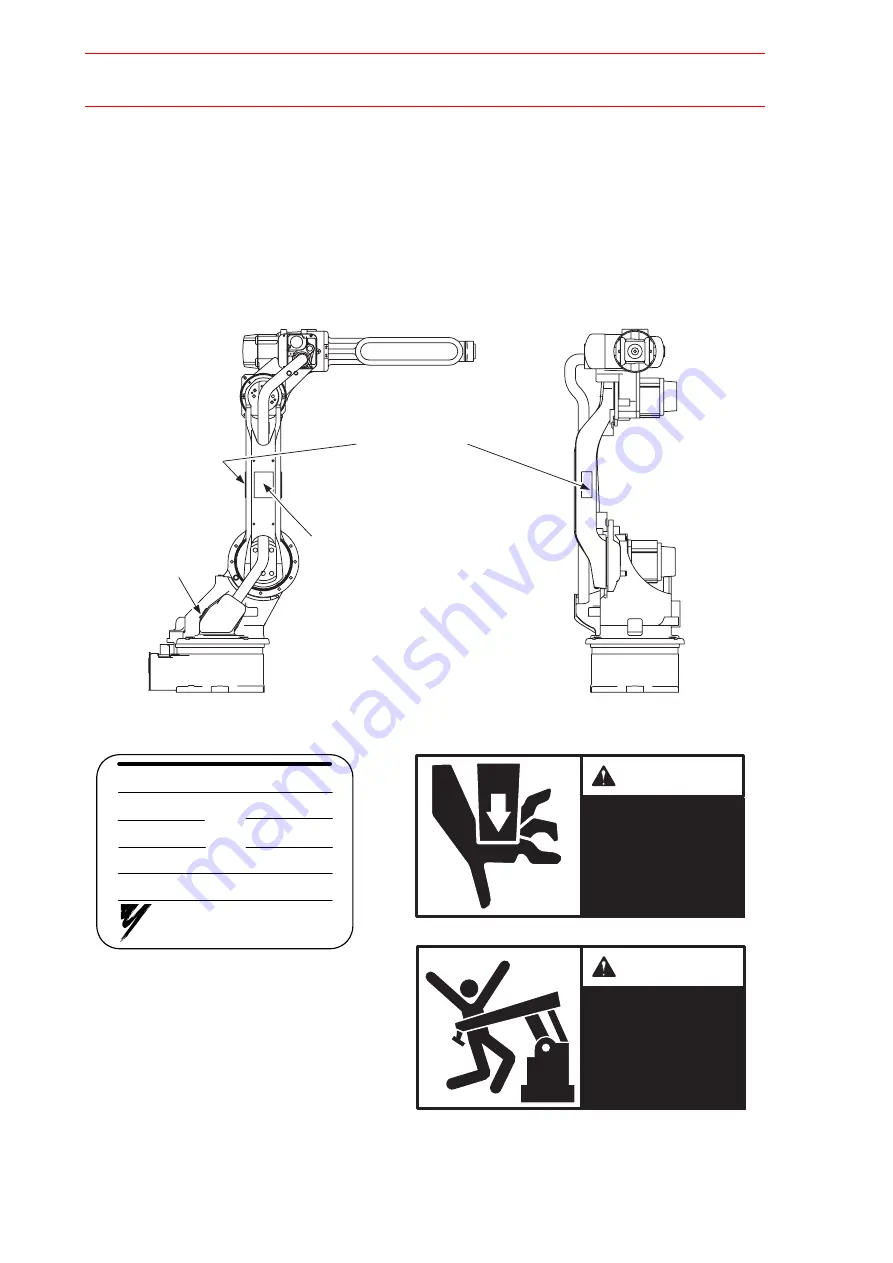

Explanation of Warning Labels

The following warning labels are attached to the manipulator.

Always follow the warnings on the labels.

Also, an identification label with important information is placed on the body of the manipula-

tor. Prior to operating the manipulator, confirm the contents.

Nameplate

WARNING

label

A

WARNING

label

B

MOTOMAN

TYPE

ORDER NO.

PAYLOAD

kg

MASS

kg

SERIAL NO.

DATE

YASKAWA ELECTRIC CORPORATION

JAPAN

Nameplate:

WARNING

Moving parts

may cause

injury

WARNING

Do not enter

robot

work area.

WARNING label A:

WARNING label B: