9

Maintenance and Inspection

9.2

Notes on Maintenance Procedures

9-5

HW1483028

HW1483028

9.2

Notes on Maintenance Procedures

9.2.1 Battery Pack Replacement

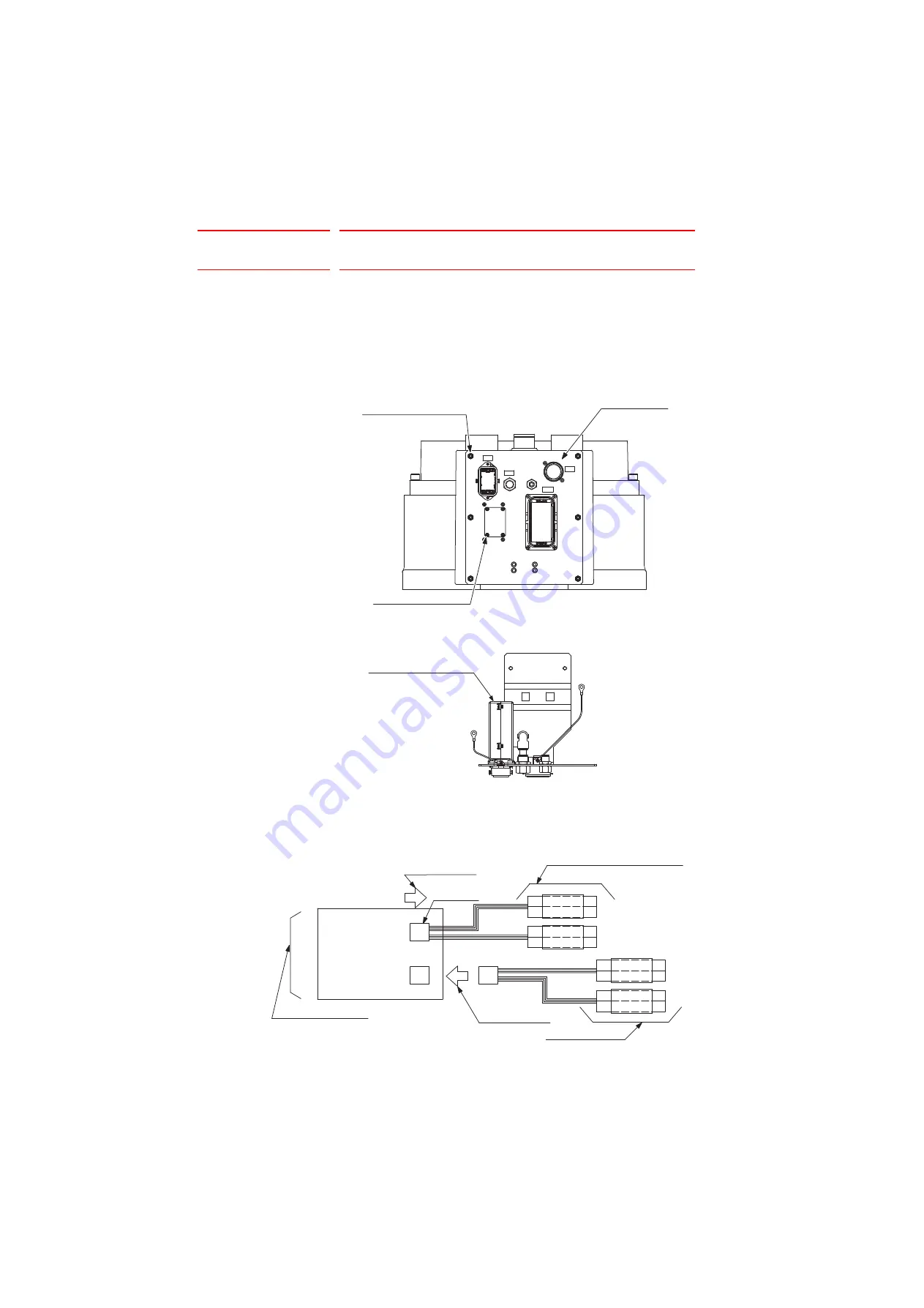

The battery packs are installed in the position shown in

.

• Battery Type: HW0470360-A

Fig. 9-2: Battery Location

Fig. 9-3: Battery Connection

2BC

AIR

S1

1BC

Connector base

Cross head APS bolt M6

(Length:12)(6 bolts)

Cross head APS bolt M4

(Length:10)(4 bolts)

Battery pack (HW0470360-A)

Back side view

Top view

See procedure 5

Connector

Battery pack before replacement

See procedure 4

New battery pack

Circuit board

(type:SGDR-EFBA02A)

42/69