9

Maintenance and Inspection

9.1

Inspection Schedule

9-3

HW1483028

HW1483028

T

he nu

mbe

rs in th

e ab

ove t

a

bl

e co

rr

espo

nd to the nu

mbe

rs in

.

13

LU-axes s

p

eed

reducers

••

Grease Gun

C

heck for

malfunction.

(Replace if

necessar

y.)

Supply

gr

ease (6000H cyc

le)

.

Repl

ace grea

se

(1

2000

H cycle

)

. See

,

ch

apt

er

9.3.4

.

••

14

R-a

xi

s spe

ed

redu

cers

••

Grease Gun

C

heck for

malfunction.

(Rep

lace if

necessar

y.)

Supply

gr

ease (6000H cyc

le)

.

Repl

ace grea

se

(1

2000

H cycle

)

. See

••

15

B,T

-axes spee

d reduce

rs

B,T

-axes ge

ars

••

Grease Gun

C

heck for

malfunction.

(Replace if

necessar

y.)

Supply gr

ease(6000H

cycle)

.

Replace greas

e

(12000H cycle)

. See

.

••

16

Overhau

l

••

1

Inspe

cti

on No. co

rre

spond

to the numb

ers

in

.

2

T

he o

ccu

rre

nce of a gre

ase le

akage

indi

ca

te

s

the

possib

ility th

at

g

rease h

as seepe

d into the

motor. Th

is can cau

se

a motor bre

akd

own. Con

tact your

Ya

ska

wa represe

nta

tive.

3

W

hen

checking

fo

r condu

ctio

n wi

th mu

lti

m

e

te

r, conn

ect th

e batter

y to

“BA

T

” and

“OBT

” of co

nne

ctors o

n th

e motor side

fo

r each

axi

s,

an

d th

en

re

mo

ve

co

nnectors on detector side for each axis fro

m

the motor

. Othe

rwise, the

h

ome

positio

n ma

y

be

lo

st.

(Refer to

.)

4

T

he grea

se

mig

ht

le

ak

o

ut fro

m

the air breather or

the

in

te

rn

al

pressure

migh

t rise i

n ca

se the

mani

pula

to

r is

used

very frequ

en

tly for

th

e a

ppl

ication

such

a

s ha

ndl

ing.

5

F

or th

e grease, refer

to

.

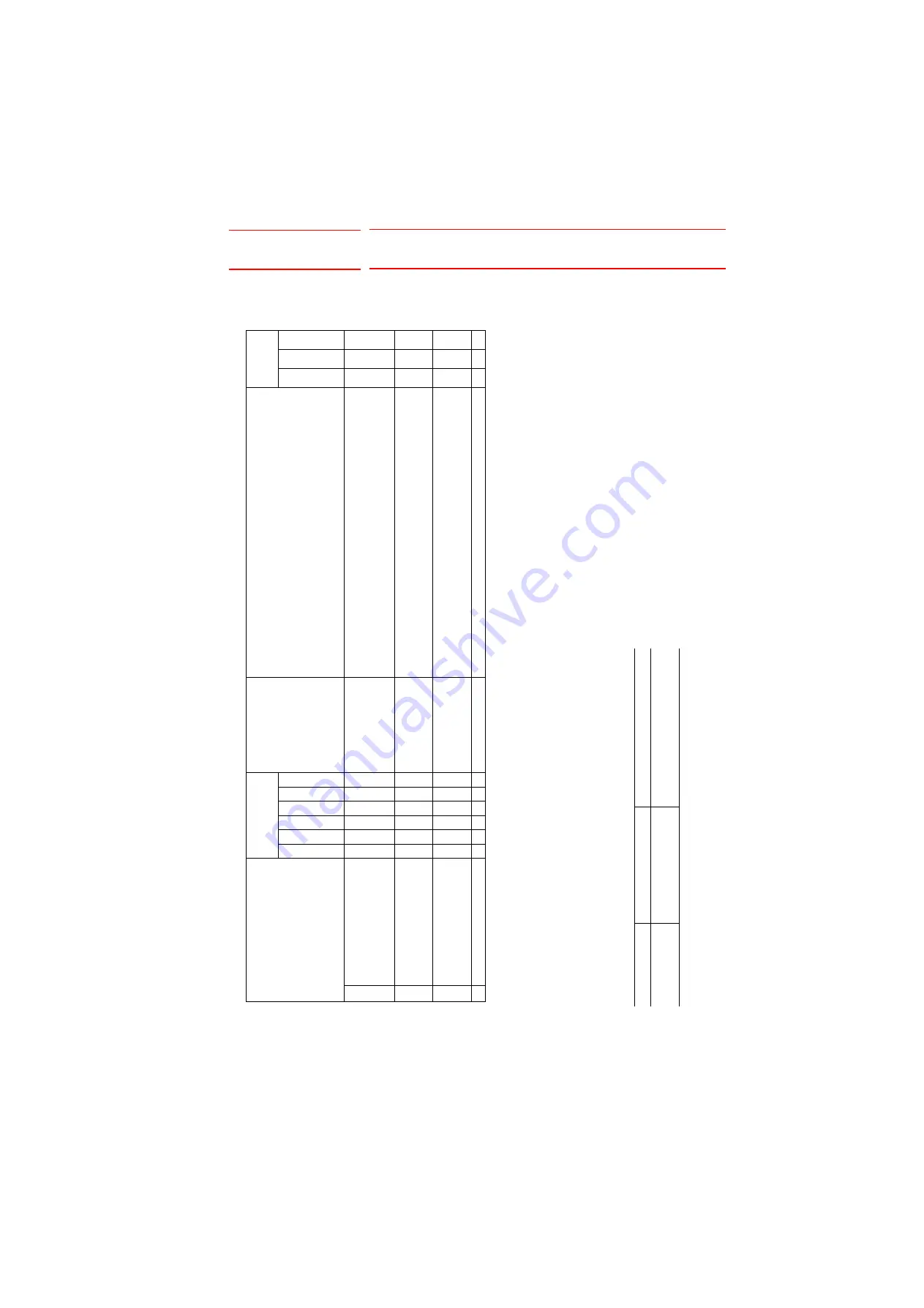

Ta

bl

e 9-

2:

Insp

ectio

n

Par

ts an

d Gr

ea

se

Used

No.

G

re

ase

Us

ed

In

spe

cted

Pa

rt

s

13

,1

4,15,16

Mo

lywhi

te

RE

No.00

S

pe

ed

redu

cers for

all

axe

s

B,T

-axe

s ge

ars

Ta

bl

e 9-

1:

Inspe

ctio

n

Item

s (

S

hee

t 2 o

f 2)

Items

1)

Sche

du

le

Me

tho

d

Op

era

tio

n

Insp

ecti

o

n

Charge

Daily

1000H

Cycle

6000H

Cycle

1200

0HC

ycl

e

2400

0HC

ycl

e

3600

0HC

ycl

e

Spec

ifi

ed

Lice

nse

e

Service

40/69