9

Maintenance and Inspection

9.3

Grease Replenishment/Exchange

9-22

HW1483270

HW1483270

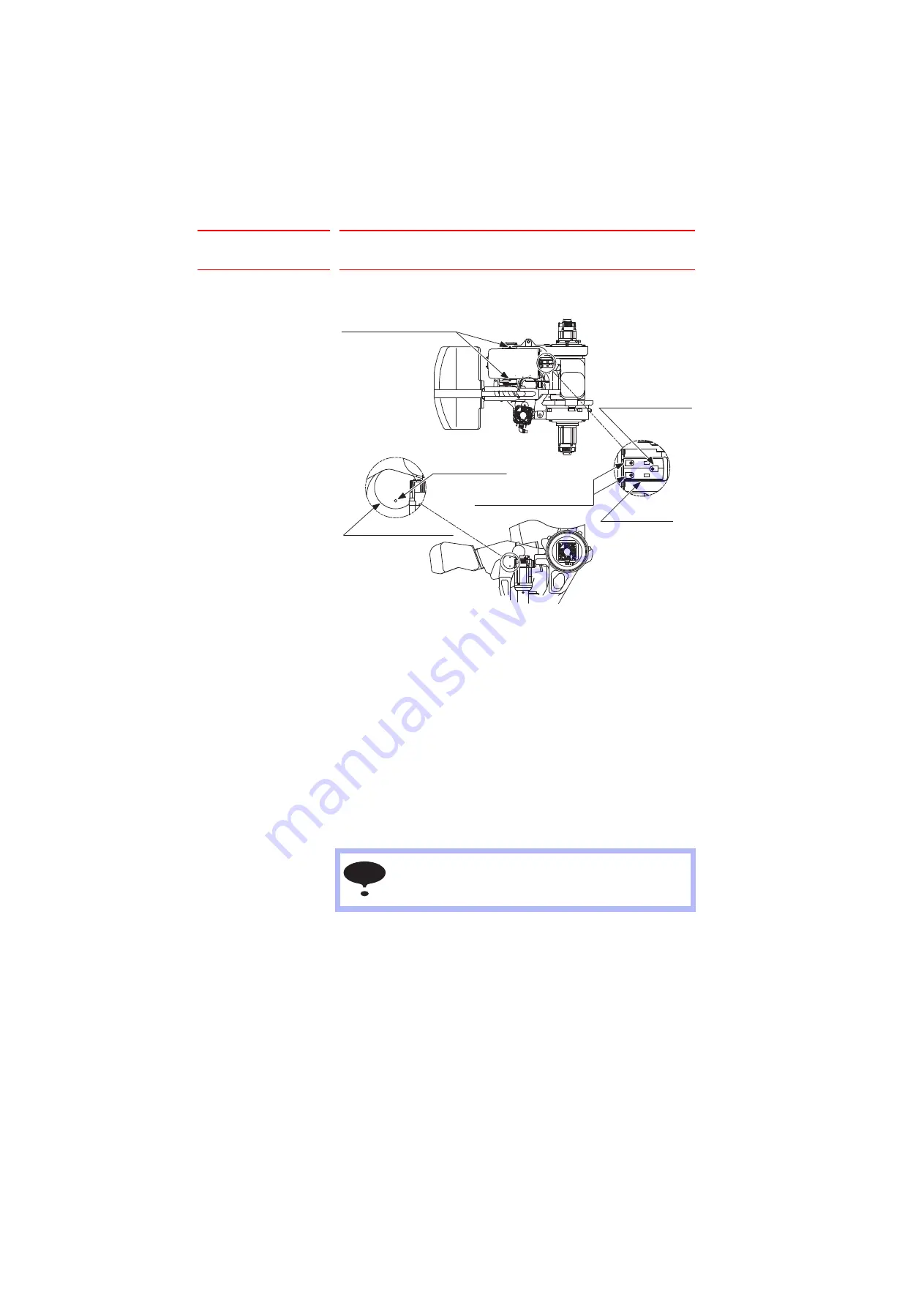

9.3.10 Grease Replenishment for Balancer Link Part

Fig. 9-12: Balancer Link Part

1. Remove the hexagon socket head plug PT1/8 from the exhaust port of

Link1. Remove the hexagon socket head plug PT1/8 (2 places) from

the exhaust port of Link2.

(Refer to

fig. 9-12 “Balancer Link Part”

.)

2. Remove the hexagon socket head plug PT1/8 from the grease inlet.

3. Install a grease zerk A-PT1/8 on the grease inlet.

(The grease zerk is delivered with the manipulator.)

4. Inject grease using a grease gun.

– Grease type:

Alvania EP grease 2

– Amount of grease:

approx. 5cc

(10cc for the 1st supply)

5. Remove the grease zerk from the grease inlet and reinstall the plug.

Tighten the plug with a tightening torque of 4.9 N

•

m (0.5 kgf

•

m).

(Apply ThreeBond 1206C to thread part of the plug.)

6. Reinstall the plug on the exhaust port of the Link1.

Reinstall the plugs (2 places) on the exhaust port of the Link2.

Tighten the screw/plugs with a tightening torque of 4.9 N

•

m (0.5 kgf

•

m).

(Apply ThreeBond 1206C to thread part of the screw/plugs.)

NOTE

The exhaust ports are used for air flow.

Do not inject excessive grease into the grease inlets.

Hexagon socket

head plug PT1/8

Hexagon socket head plug PT1/8

Hexagon socket head

plug PT1/8 (2 plugs)

Link1 Grease inlet

Needle bearing

Link2 Tapered roller bearing

(2 bearings)

Link1 Exhaust port

Link2 Grease inlet

Link2 Exhaust port

64/88