3

Installation

3.2

Mounting Procedures for Manipulator Base

3-4

HW1483270

HW1483270

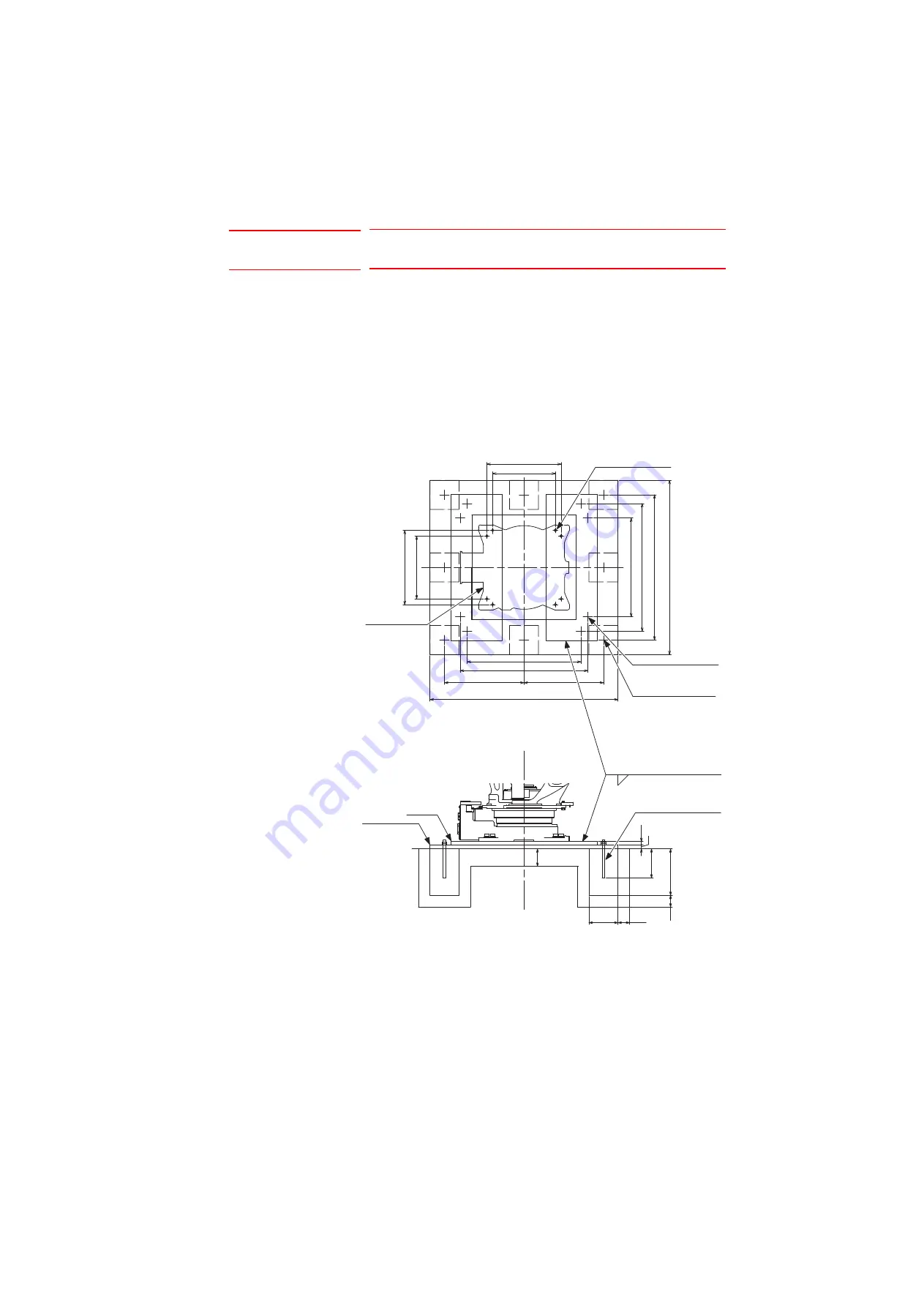

3.2.2 Mounting the Manipulator Directly on the Floor

The floor should be strong enough to support the manipulator. Construct

a solid foundation with the appropriate thickness to withstand maximum

repulsion forces of the manipulator. As a rough standard, when there is a

concrete thickness (floor) of 150 mm or more, the manipulator base can

be fixed directly to the floor with anchor bolts M16. Before mounting the

manipulator, however, check that the floor is level and that all cracks, etc.

are repaired. A non-concrete floor or a floor less than 150 mm thick is

insufficient for mounting, even if the floor is concrete.

Fig. 3-3: Mounting on the Floor (Example for the Foundation)

FL

The fixing screw and bases should be prepared by customer.

B: Screw M24 (length: 70mm) (8 screws), spring washers

A: Screw M20 (length: 70mm) (8 screws), spring washers, flat washers

10

Weld these after installation

and adjustment.

(length: 315 mm)

JA type anchor bolts M24

The surface must

be level and even.

Base B

Base A

Screw B (8 screws)

Tapped hole M24 (base B)

28 dia. (base A) (8 holes)

28 dia. (base B) (8 holes)

Screw A (8 screws)

Manipulator base

Tapped hole M20

1100

1100

685

685

1500

1620

100

250

36

27

150

100

400

250

o

850

1250

980

640

540

640

540

17/88