6 Test of Program Operation

6.1 Movement of the Axes

6-3

168283-1CD

168283-1CD

Hardware Installation &

Software Upgrade

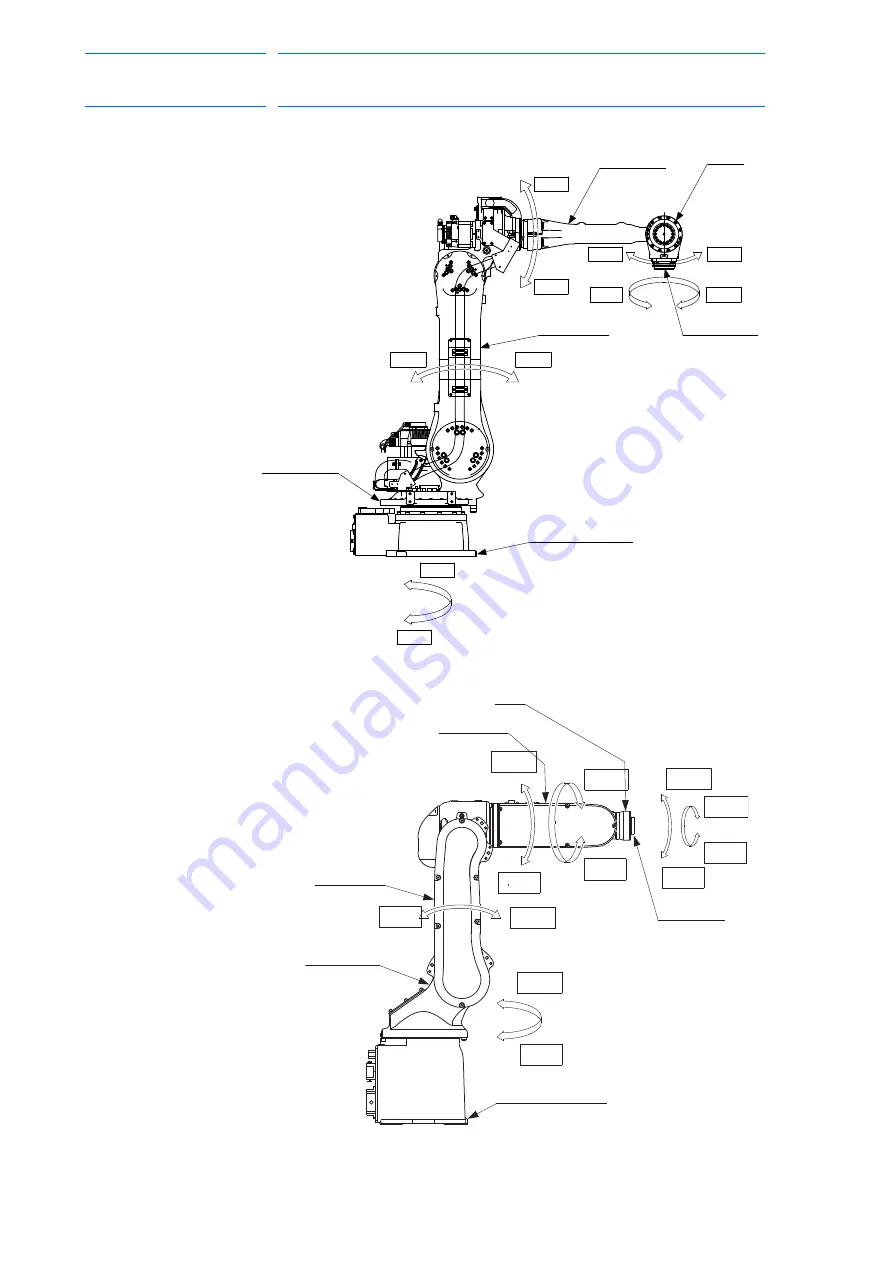

Fig. 6-2: 5-Axis Manipulator

Fig. 6-3: 6-Axis Manipulator

A

4-

A

3-

A

4+

A

3+

A

2-

A

2+

A

1-

A

1+

A

0-

A

0+

Wrist

Wrist flange

Lower arm

L-arm

Upper arm

U-arm

Rotary head

S-head

Manipulator base

Wrist

Upper arm

(U-arm)

Wrist flange

Manipulator base

Lower arm

(L-arm)

Rotary head

A

5-

A

5+

A

4+

A

4-

A

3-

A

3+

A

2-

A

2+

A

1-

A

1+

A

0-

A

0+

49 of 121