3

Installation

3.2 Mounting Procedures for Manipulator Base

3-2

173124-1CD

HW1482991

MPL300

II

3.2

Mounting Procedures for Manipulator Base

The manipulator should be firmly mounted on a baseplate or foundation

strong enough to support the manipulator and withstand repulsion forces

during acceleration and deceleration.

Construct a solid foundation with the appropriate thickness to withstand

maximum repulsion forces of the manipulator as shown in

“Manipulator Repulsion Force and Torque”

.

During installation, if the flatness is not right, the manipulator shape may

be deformed and its functional ability may be compromised. The flatness

for baseplate must be kept at 0.5 mm or less. Fix the manipulator base as

described in

section 3.2.1 “Mounting the Manipulator and Fixture on the

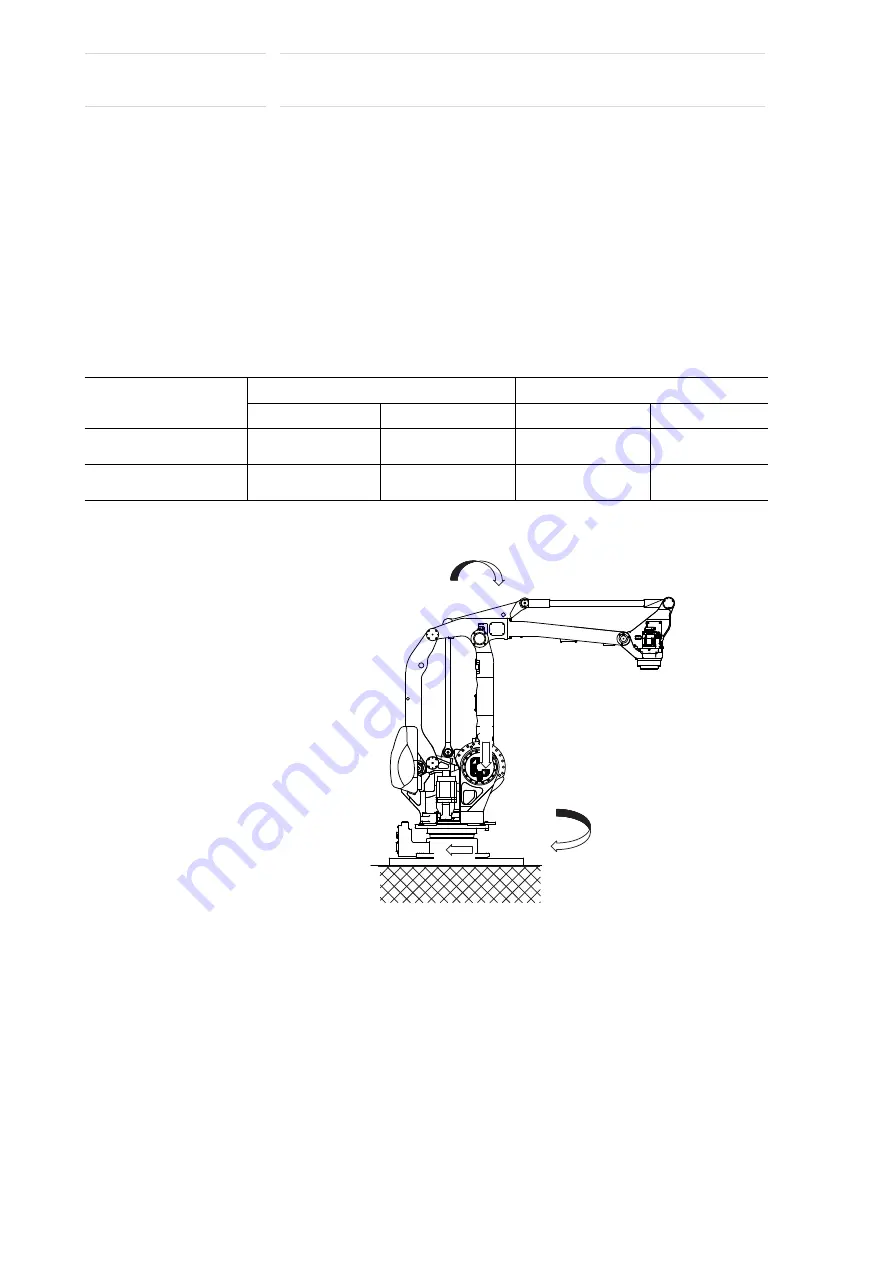

Fig. 3-1: Manipulator Repulsion Force and Torque

Table 3-1: Manipulator Repulsion Force and Torque

Horizontal rotation

Vertical rotation

Repulsion force F

H

Torque M

H

Repulsion force F

V

Torque M

V

Emergency stop

20580 N

(2100 kgf)

39200 N•m

(4000 kgf•m)

49980 N

(5100 kgf)

62720 N•m

(6400 kgf•m)

Acceleration/deceleration 6370 N

(650 kgf)

11760 N•m

(1200 kgf•m)

21560 N

(2200 kgf)

15680 N•m

(1600 kgf•m)

M

V

M

H

F

V

F

H

22 of 100