9-2

1731

24-1

C

D

HW1482991

9

M

aintena

nce an

d Inspection

9.1

Inspe

ction

Sche

du

le

MPL3

00

II

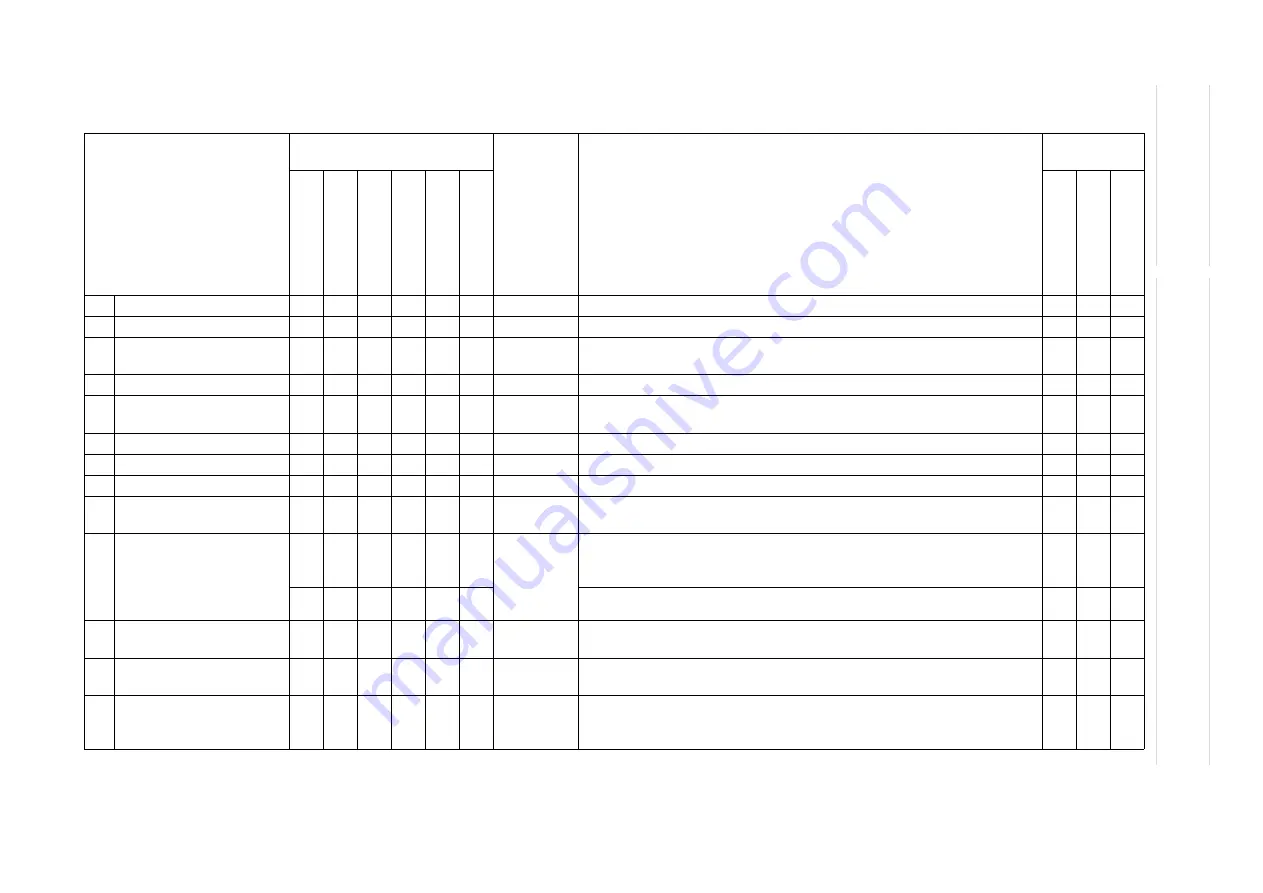

Table 9-1: Inspection Items (Sheet 1 of 2)

Items

1)

Schedule

Method

Operation

Inspection

Charge

Da

ily

10

00H Cy

cle

50

00H Cy

cle

90

00H Cy

cle

18

000

H

36

000

H

S

p

ec

if

ie

d Pe

rs

on

Li

ce

n

s

ee

Ser

vice Com

p

an

y

1

Alignment mark

•

Visual

Check alignment mark accordance and damage at the home position.

• • •

2

External lead

•

Visual

Check for damage and deterioration of leads.

• • •

3

Working area and

manipulator

•

Visual

Clean the work area if dust or spatter is present. Check for damage and

outside cracks.

• • •

4

Motors for L- and U-axes

•

Visual

Check for grease leakage.

2)

• • •

5

Baseplate mounting bolts

•

Spanner

Wrench

Tighten loose bolts. Replace if necessary.

• • •

6

Connector base

•

Manual

Check for loose connectors and tighten if necessary.

• • •

7

LU-axis connectors

•

Manual

Check for loose connectors and tighten if necessary.

• • •

8

Connectors in S-head

•

Manual

Check for loose connectors.

• • •

9

L-axis balancer

•

Grease

Gun, Visual

Supply grease.

Check for loose screw nuts and shafts, and tighten if necessary.

• •

10 Wire harness in

manipulator

(Wires for S-, L-, and U-

axes)

(Wires for T-axis)

•

Multimeter,

Visual

Check for conduction between the main connector of base and intermediate

connector with manually shaking the wire. Check for wear of protective

spring

3)

• •

•

Replace

4)

•

11

Links/Connections

•

Visual,

Manual

Move the L- and U-axes back and forth, up and down to check any backlash.

Replenish grease

5)

See

.

• •

12 Battery pack in manipulator

•

Screwdriver,

Wrench

Replace the battery pack when the battery alarm occurs or the manipulator

drove for 36000H. See

• •

13 S-axis speed reducer

• •

Grease Gun Check for malfunction. (Replace if necessary.)

Replenish grease

(5000H cycle). See

.

Exchange grease

(9000H cycle). See

.

• •

65 of 100