6

Allowable Load for Wrist Axis and Wrist Flange

6.1 Allowable Wrist Load

6-1

173124-1CD

HW1482991

MPL300

II

6

Allowable Load for Wrist Axis and Wrist Flange

6.1

Allowable Wrist Load

The allowable wrist load including the weight of the mount/gripper is

160 kg maximum.

1. The total moment of inertia (GD

2

/4) of T-axis should be within the

value shown in

Table 6-1 “Allowable Total Inertia”

.

2. When the inertia of the volume load on the flange is small, the

eccentricity of load center measured from T-axis flange rotation center

is in the range shown in

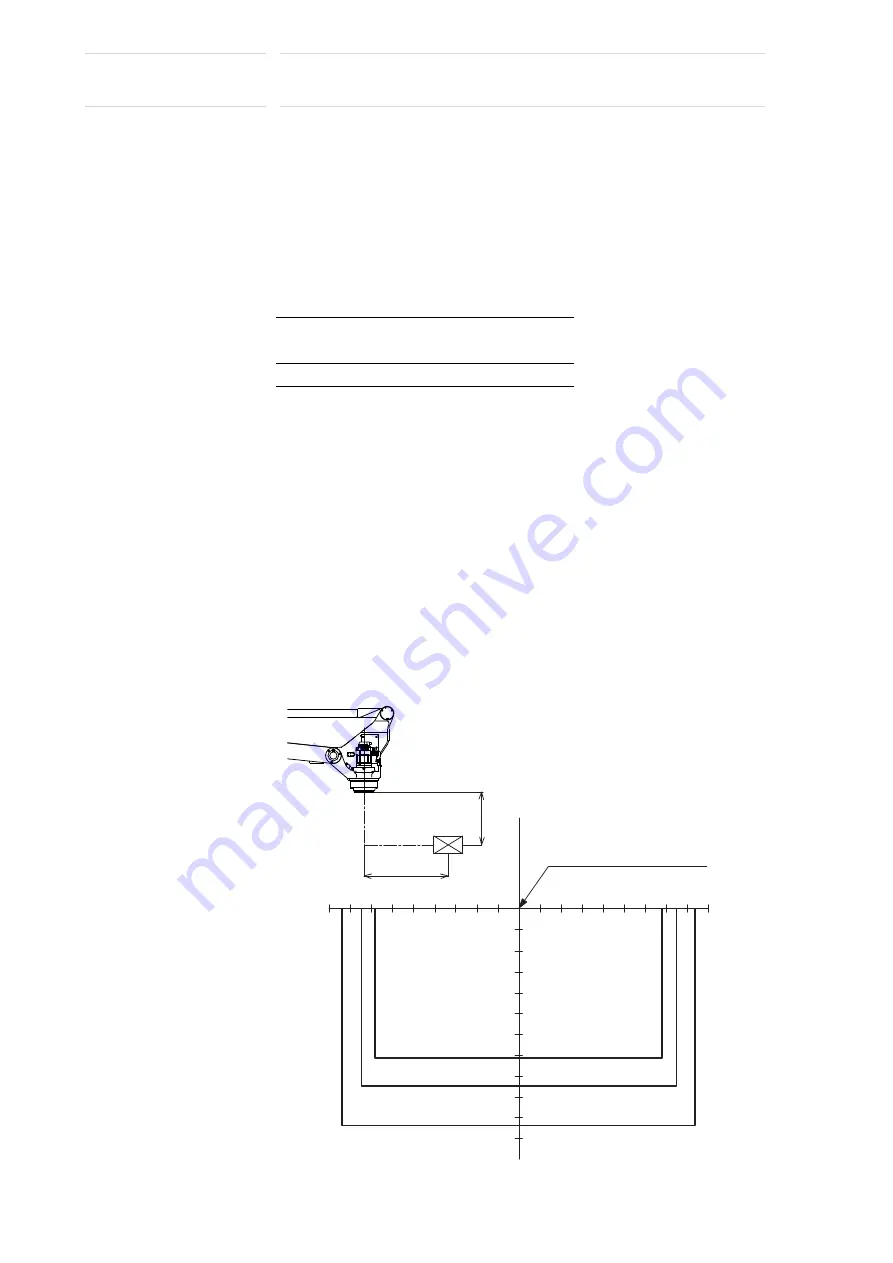

Fig. 6-1 “Moment Arm Rating for MPL300 II”

When the inertia of the volume load on the flange (Ji) is large, use the

following formula to calculate the eccentricity L

T

.

Fig. 6-1: Moment Arm Rating for MPL300

II

Table 6-1: Allowable Total Inertia

T- Axis Total Moment of Inertia (GD

2

/4)

kg•m

2

140 kg•m

2

J=Ji+WL

2

T

J

Ji

W

LT

: Total inertia (GD

2

/4) of the T-axis (kgžm

2

)

: Inertia of the volume load on the flange (kgžm

2

)

: Payload (kg)

: Eccentricity (mm)

Formula:

Center of T-axis flange rotation

LB

LT

W=300 kg

W=250 kg

W=200 kg

900 800 700 600 500 400 300 200 100

100 200 300 400 500 600 700 800 900

100

200

300

400

500

600

700

800

900

1000

1100

LB (mm)

LT (mm)

52 of 100