10-2

18078

8-1CD

HW1484370

10

M

a

in

te

nan

ce

and

Inspe

ctio

n

10

.1

In

sp

ectio

n

Sched

ule

MPX

26

00

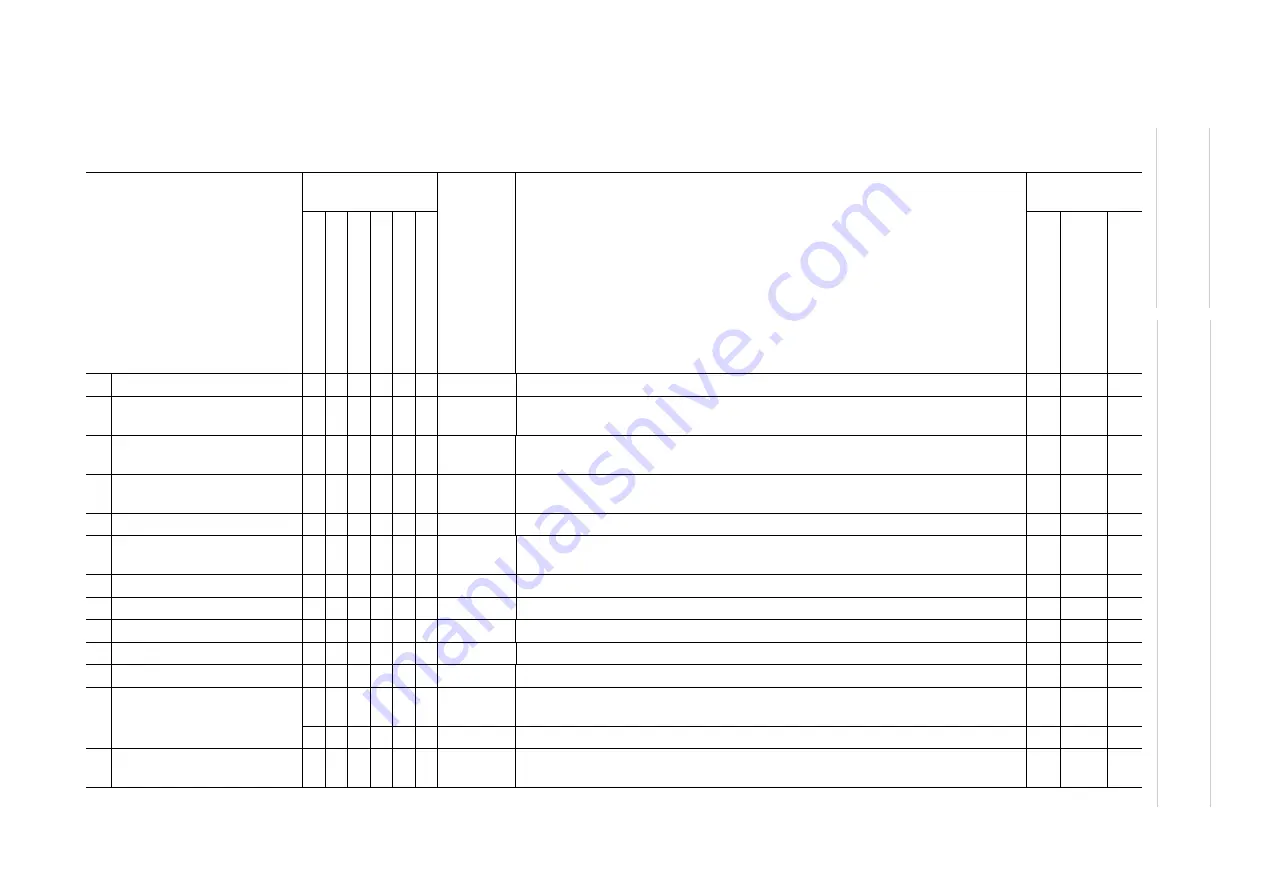

Table 10-1: Inspection Schedule

1)

Item

Schedule

Method

Operation

Inspection

Charge

Daily

100

0HCyc

le

600

0HCyc

le

120

00HCy

cle

240

00HCy

cle

360

00HCy

cle

S

p

ec

ifi

ed

p

e

rs

on

ne

l

(Cust

o

mer)

Licen

se

e

(P

erson

wh

o

is

q

u

al

if

ie

d by

Y

A

SKA

W

A)

Service

Comp

a

n

y

(Y

ASKA

W

A

)

1

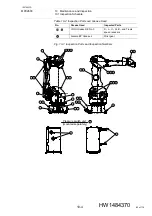

Manipulator exterior

•

Visual

Check for crack or damages.

• •

•

2

Manipulator motion, noise,

and vibration

•

Visual

Noise

Check for abnormality/

• •

•

3

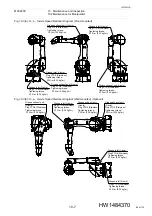

Air tube, air leakage

•

Visual

Manual

Check for come off, wear, or damages.

Check for air leakage.

• •

•

4

Paint removal and cleaning

•

Visual

Manual

Remove adhered paint if any.

• •

•

5

Pressure switch unit setting

•

Visual

Check the value if it is within the proper value range.

• •

•

6

Base mounting bolts

•

Spanner

Wrench

Tighten loose bolts. Replace if necessary.

• •

•

7

Cover mounting screws

•

Wrench

Tighten loose bolts. Replace if necessary.

• •

•

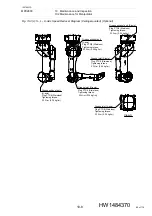

8

S-, L-, and U-axis motors

•

Visual

Check for grease leakage.

2)

•

•

9

Motor connectors

•

Manual

Check for loose connectors.

•

•

10 Motor part

•

Visual

Check for filter clogging.

•

•

11 Air seals for enclosure

•

Visual

Check for wear or tear. Replace if necessary.

•

•

12 Internal cables

•

Visual

Multi-meter

Check for conduction between the main connector of the base and the terminal by

manually shaking the wire. Check for wear on the protective spring.

3)

•

•

•

Replace the cables.

4)

•

13 Battery in manipulator

•

Replace the battery pack when the battery alarm occurs or the manipulator drove for

36000H.

•

•

83 of 116