10 Maintenance and Inspection

10.2Maintenance for Manipulator

10-9

180788-1CD

HW1484370

MPX2600

1. Before injecting grease, the posture of the manipulator must be set as

indicated in

Table 10-3 “Recommended Posture for Grease Injection”

If it is difficult to make the recommended posture because of external

cabling or etc., adjust the posture as much as possible to make the

position of grease inlet located in the lower part and the position of

exhaust port located in the upper part. If the exhaust port is located in

the lower part, grease may not be exchanged properly.

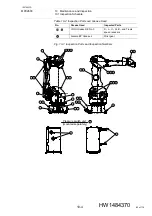

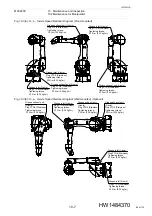

Table 10-3: Recommended Posture for Grease Injection

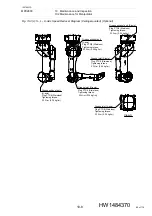

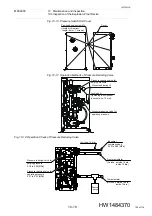

2. Remove the hexagon socket head plugs from the grease inlet and

grease exhaust port.

3. Install a grease zerk A-PT3/8 to the grease inlet.

(The grease zerk is delivered with the manipulator.)

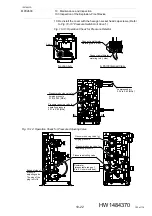

4. Inject the grease through the grease inlet using a grease gun.

– Grease type:

VIGO grease RE No.0

– Recommended grease lubricator: Powerlube P3C (made by

Macnaught)

– Amount of grease:

7 g/s or less

(For example, if grease is supplied from the lubricator at 2 times/s,

set the amount to 3.5 g/time or less.)

– Air supply pressure of grease pump: Approximately 0.3 MPa or less

Table 10-4: Amount of Grease

5. The old grease is discharged from the grease exhaust port. At this

time, stop injection when the mixture of the old grease and the new

grease in an equal ratio is seen.

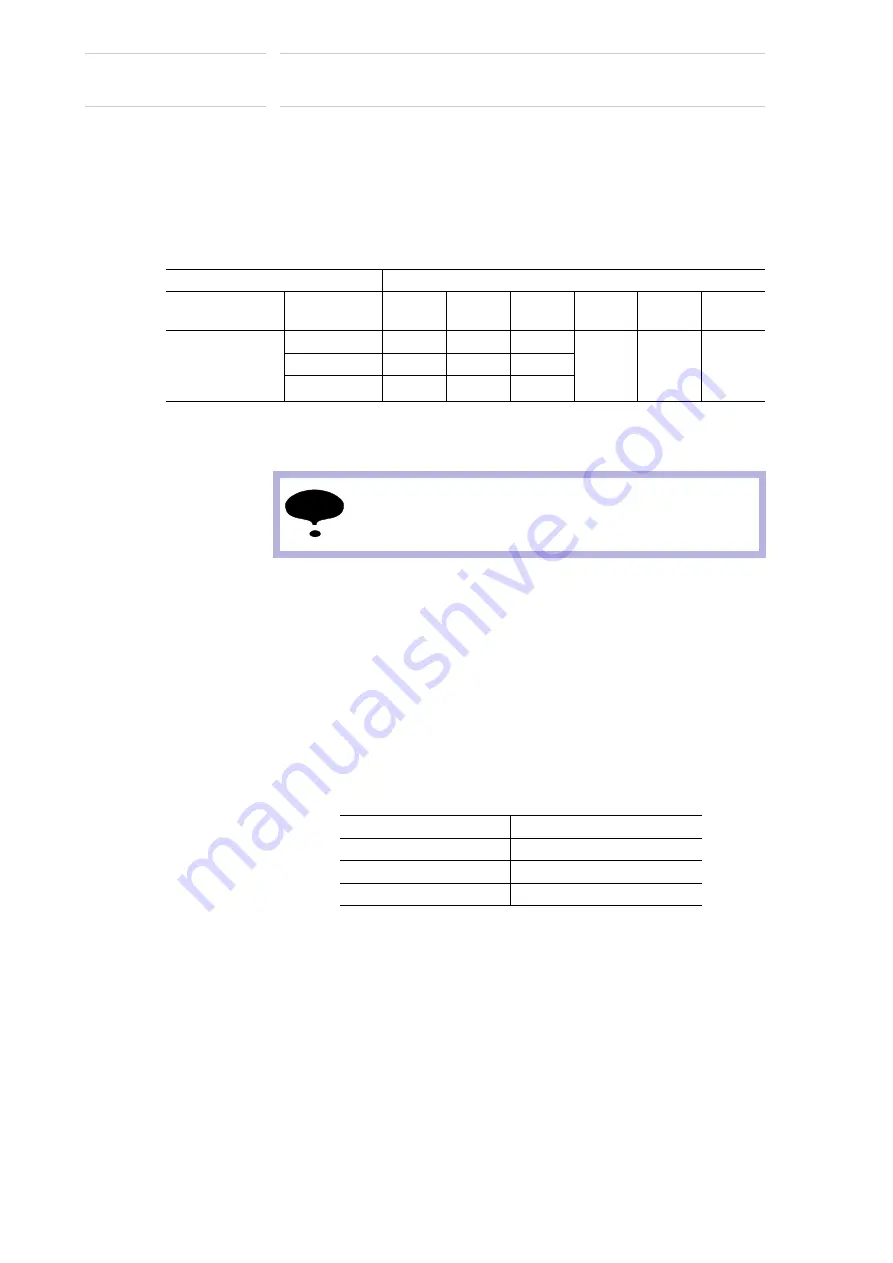

Posture

Mounting

Condition

Axis to inject

S-axis

L-axis

U-axis

R-axis

B-axis

T-axis

Floor-mounted

Wall-mounted

Ceiling-mounted

S-axis

0°

Any

Any

Any Any

Any

L-axis

Any

0°

Any

U-axis

Any

0°

0°

NOTE

The positions of grease inlet and exhaust port are different

depending on the mounting condition of the manipulator.

Confirm the positions beforehand.

Axis to exchange grease Amount of grease

S-axis

Approx.4200 g

L-axis

Approx.2300 g

U-axis

Approx.1650 g

90 of 116