10 Maintenance and Inspection

10.2Maintenance for Manipulator

10-13

180788-1CD

HW1484370

MPX2600

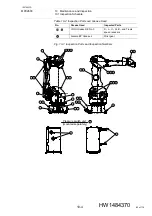

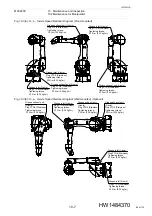

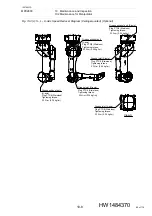

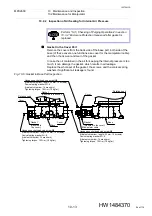

10.2.2 Inspection of Air Sealing for Internal Air Pressure

Gasket in the Cover Part

Remove the covers from the back side of the base part, both side of the

base (of these covers, one functions as a cover for the manipulator cable),

and then check wear and tear of the gasket.

In case the oil contained in the air for keeping the internal pressure is too

much, it can damage the gasket, which results in air leakage.

Replace the whole set of the gasket, the screws, and the conical spring

washers if significant air leakage is found.

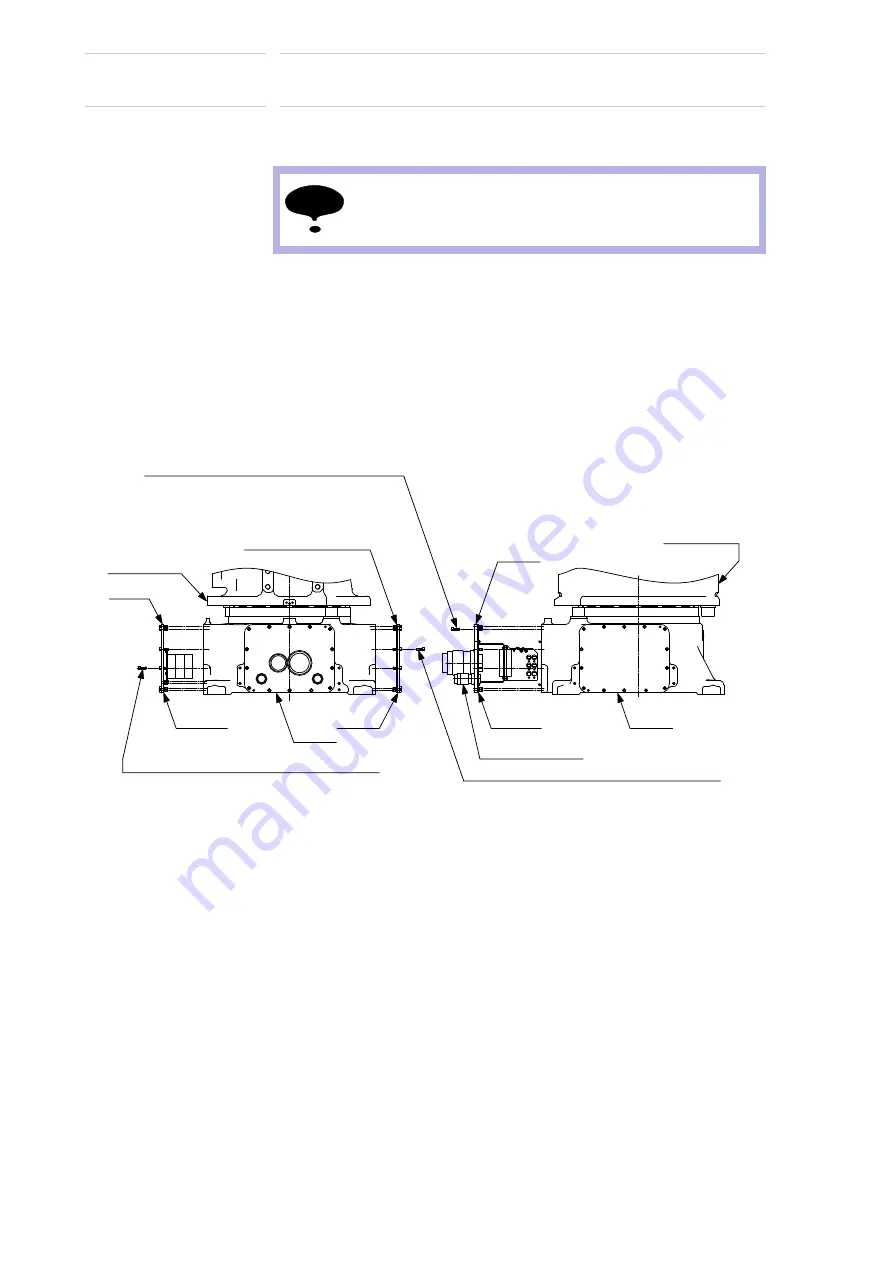

Fig. 10-6: Gasket in Base Part Inspection

NOTE

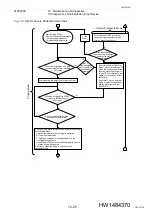

Perform “3-(1) Checking of Purging Operations” in

10.3.2 “Enclosure Protection Sequence”

after gasket is

replaced.

Base

Base

Gasket

(Adhered to

the cover)

Gasket

(Adhered to the cover)

Cover

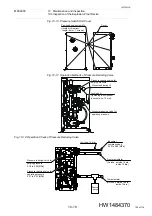

Hexagon socket head cap screw M6

(trivalent chromium, length: 25 mm, 14 screws)

Conical spring washer 2H-6

(trivalent chromium, 14 washers)

Tightening torque: 10 N•m (1.0 kgf•m)

Gasket

(Adhered to the cover)

Cover

Hexagon socket head cap screw M6

(trivalent chromium, length: 25 mm, 14 screws)

Conical spring washer 2H-6

(trivalent chromium, 14 washers)

Tightening torque: 10 N•m (1.0 kgf•m)

Hexagon socket head cap screw M6

(trivalent chromium, length: 25 mm, 14 screws)

Conical spring washer 2H-6

(trivalent chromium, 14 washers)

Tightening torque: 10 N•m (1.0 kgf•m)

Cover

Rotating head

Manipulator cable

Rotating head

94 of 116