10 Maintenance and Inspection

10.2Maintenance for Manipulator

10-5

180788-1CD

HW1484370

MPX2600

10.2

Maintenance for Manipulator

10.2.1 Grease Replenishment/Replacement

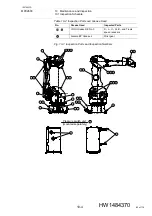

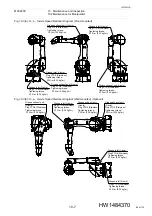

Fig. 10-1 “Inspection Parts and Inspection Numbers”

shows the location of

the components of the manipulator.

Replenish or replace the grease for the following sections:

I)

Wrist gears

II) S-, L-, and U-axis speed reducers

III) R-, B-, and T-axis speed reducers

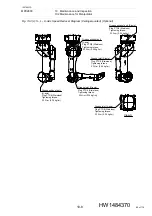

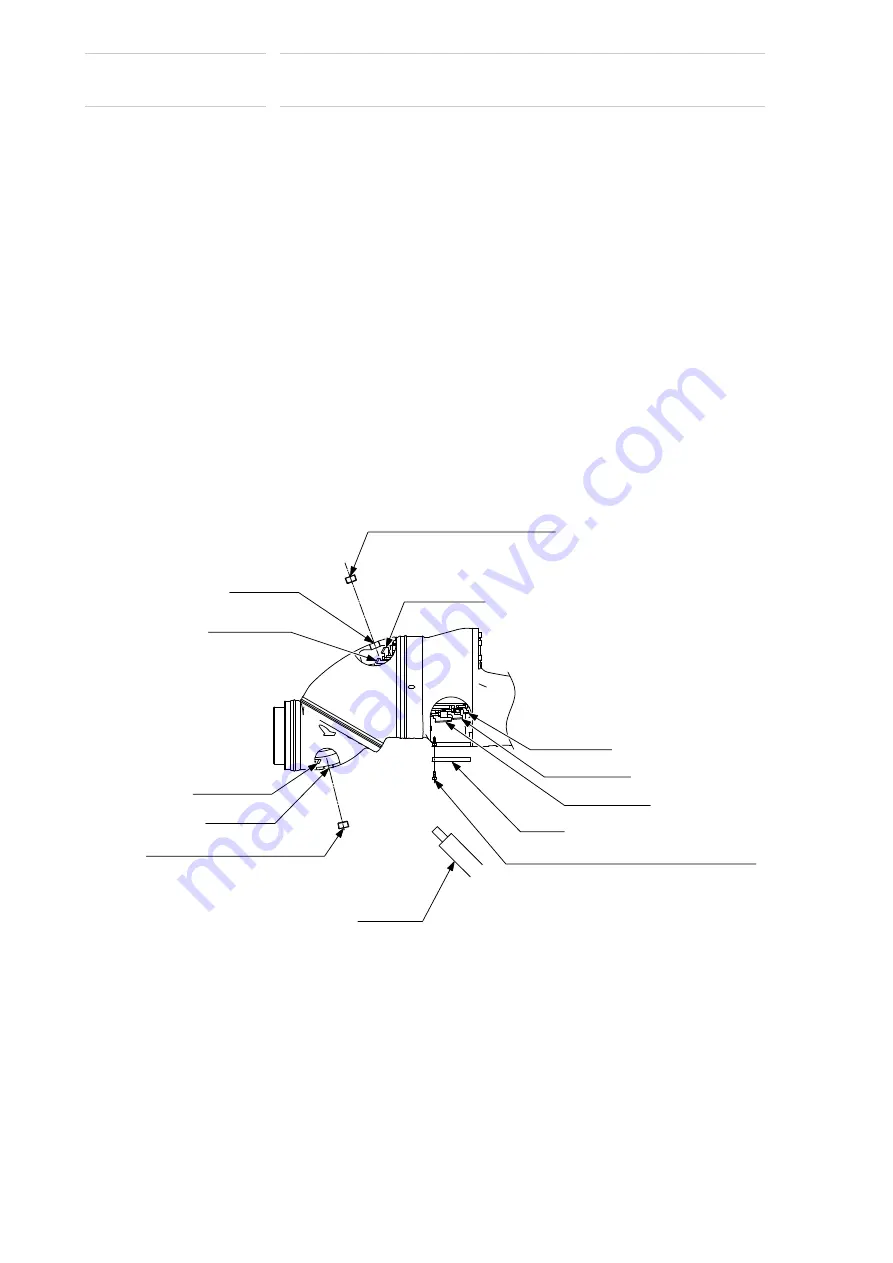

10.2.1.1 Grease Replacement Procedures for Wrist Gears

Remove the plugs each plug and cover, apply Alvania EP grease 2 on the

gear teeth of gears R1, B1, B2, T1, T2, and T3 by using a grease gun.

Apply seal tape on the thread part of each plug, then reinstall the plugs.

(Each plug must be tightened with the specified tightening torque.)

Fig. 10-2: Wrist Gears

Hexagon socket head cap screw M4

(trivalent chromium , length: 12 mm, 6 screws)

Conical spring washer 2H-4

(trivalent chromium , 6 washers)

Tightening torque 2.4 N•m (0.24 kgf•m)

R- axis gear R1

B- axis gear B1

T- axis gear T1

Cover

Grease gun

Plug

Hexagon socket head plug PT1/2

Tightening torque 39 N•m (4 kgf•m)

Grease inlet

B-axis gear B2

Plug

Hexagon socket head plug PT1/2

Tightening torque 39 N•m (4 kgf•m)

T-axis gear T3

Grease inlet

T-axis gear T2

86 of 116