10-18

180788-1CD

HW1484370

10 Maintenance and Inspection

10.3 Inspection of the Explosion-Proof Device

MPX2600

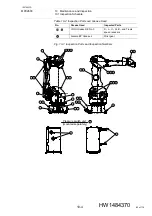

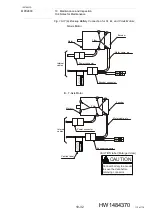

10.3.1.3 Operation Check of Pressure Reducing Valve

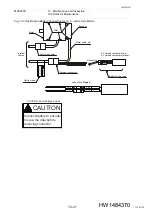

Measure the air supply pressure of the air for the explosion-proof in the

pressure switch unit by using a pressure gauge.

For the pressure gauge connection, refer to

.

The pressure gauge, joints and air tubes used for this inspection are

prepared by customer.

1. Turn OFF the power supply to the DX200.

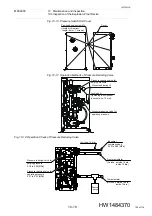

2. Unscrew the hexagon socket head cap screws to remove the pressure

unit cover. (Refer to

Fig. 10-10 “Pressure Switch Unit Cover”

.)

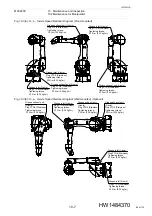

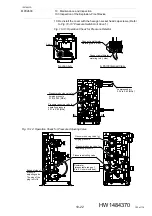

, connect the pressure gauge between the

pressure switch unit and the manipulator.

4. Set the pressure of both purging air and operation air reducing valves

as shown in

Table 10-9 “List of Setting Value for Pressure Reducing

Valve for Purging Pressure and OperatingPressure”

Refer to

section 10.3.1.2 “Operation Method of Pressure Reducing

for the reducing valve operation.

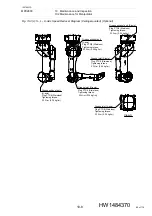

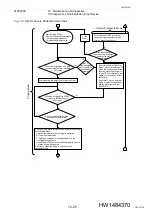

5. Turn ON the power supply to the DX200 and start purging. Check that

the pressure is keeping between 0.18 MPa and 0.20 MPa while

purging.

6. After purging is complete, wait for a few minutes and check that the

pressure is declined between 0.01 MPa and 0.02 MPa.

(Immediately after the purging operation, pressure may fluctuate.

Therefore, wait for a few minutes after completing the purging to check

the pressure.)

7. Turn OFF the power supply to the DX200 and then, re-install the cover

with the hexagon socket head cap screws. (Refer to

.)

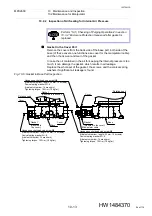

Table 10-9: List of Setting Value for Pressure Reducing Valve for Purging

Pressure and OperatingPressure

Pressure [MPa]

Pressure reducing valve

for purging pressure

0.18 to 0.20

Pressure reducing valve

for the operating pressure

0.01 to 0.02

99 of 116