3

Installation

3.1 Safeguarding Installation

3-2

167109-1CD

HW1482308

MS165

3.1

Safeguarding Installation

To insure safety, be sure to install safeguarding. It prevents unforeseen

accidents with personnel and damage to equipment. Refer to the quoted

clause for your information and guidance.

Responsibility for Safeguarding (ISO10218)

The user of a manipulator or robot system shall ensure that safeguards

are provided and used in accordance with Sections 6, 7, and 8 of this

standard. The means and degree of safeguarding, including any

redundancies, shall correspond directly to the type and level of hazard

presented by the robot system consistent with the robot application.

Safeguarding may include but not be limited to safeguarding devices,

barriers, interlock barriers, perimeter guarding, awareness barriers, and

awareness signals.

3.2

Mounting Procedures for Manipulator Base

The manipulator should be firmly mounted on a baseplate or foundation

strong enough to support the manipulator and withstand reaction forces

during acceleration and deceleration.

Construct a solid foundation with the appropriate thickness to withstand

maximum reaction forces of the manipulator referring to

“Manipulator Reaction Force and Torque”

A baseplate flatness must be kept at 0.5 mm or less: insufficient flatness

of installation surface may deform the manipulator shape and affect its

functional abilities. Mount the manipulator base as instructed in

chapter 3.2.1 “Mounting Example”

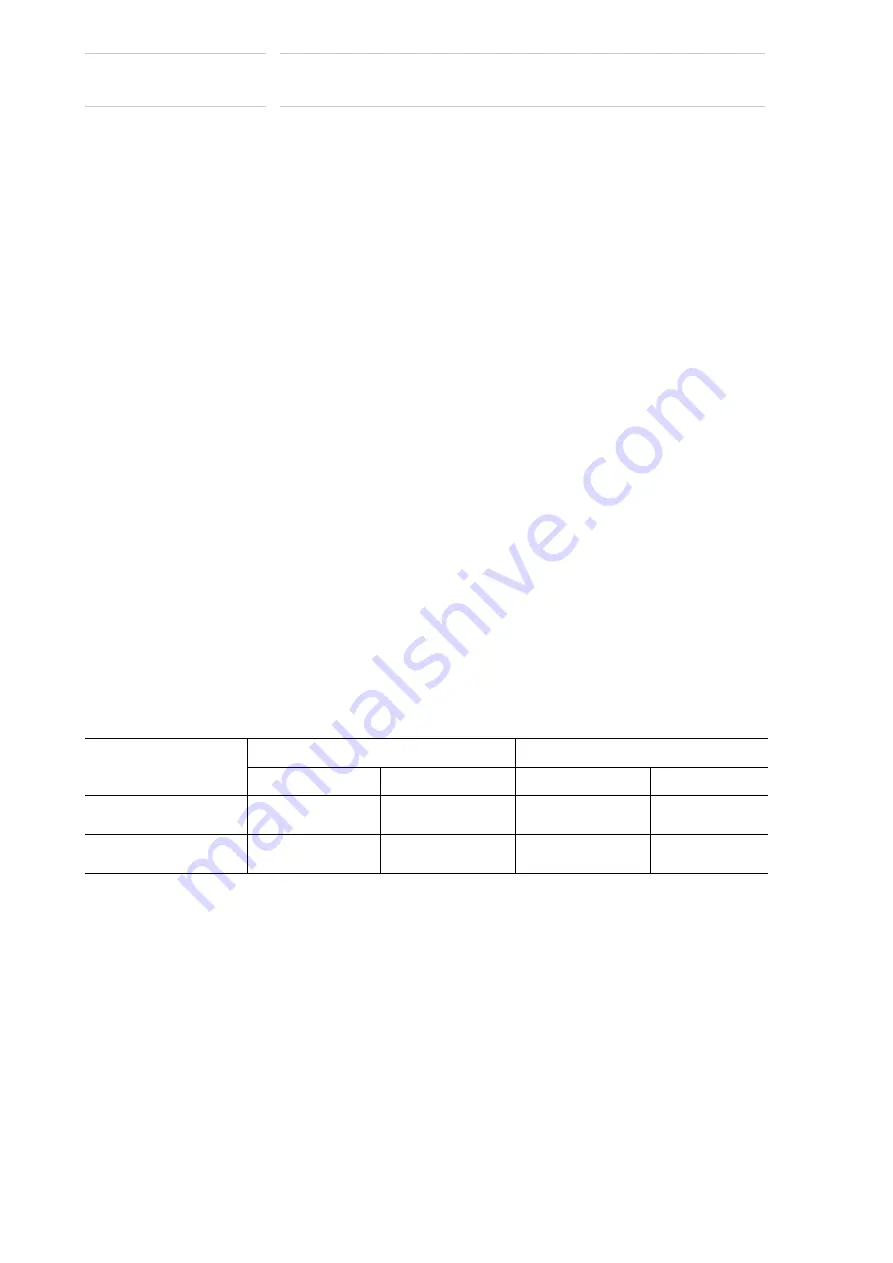

Table 3-1: Manipulator Reaction Force and Torque

Horizontal rotation

Vertical rotation

Reaction force F

H

Torque M

H

Reaction force F

V

Torque M

V

Emergency stop

24000N

(2500kgf)

37630 N•m

(3840 kgf•m)

15680N

(1600kgf)

49000 N•m

(5000 kgf•m)

Acceleration/deceleration 6370N

(650kgf)

9400 N•m

(960 kgf•m)

4900N

(500kgf)

22050 N•m

(2250kgf•m)

22 of 100