9-13

167109-1CD

HW1482308

9

Maintenance and Inspection

9.3 Grease Exchange

MS165

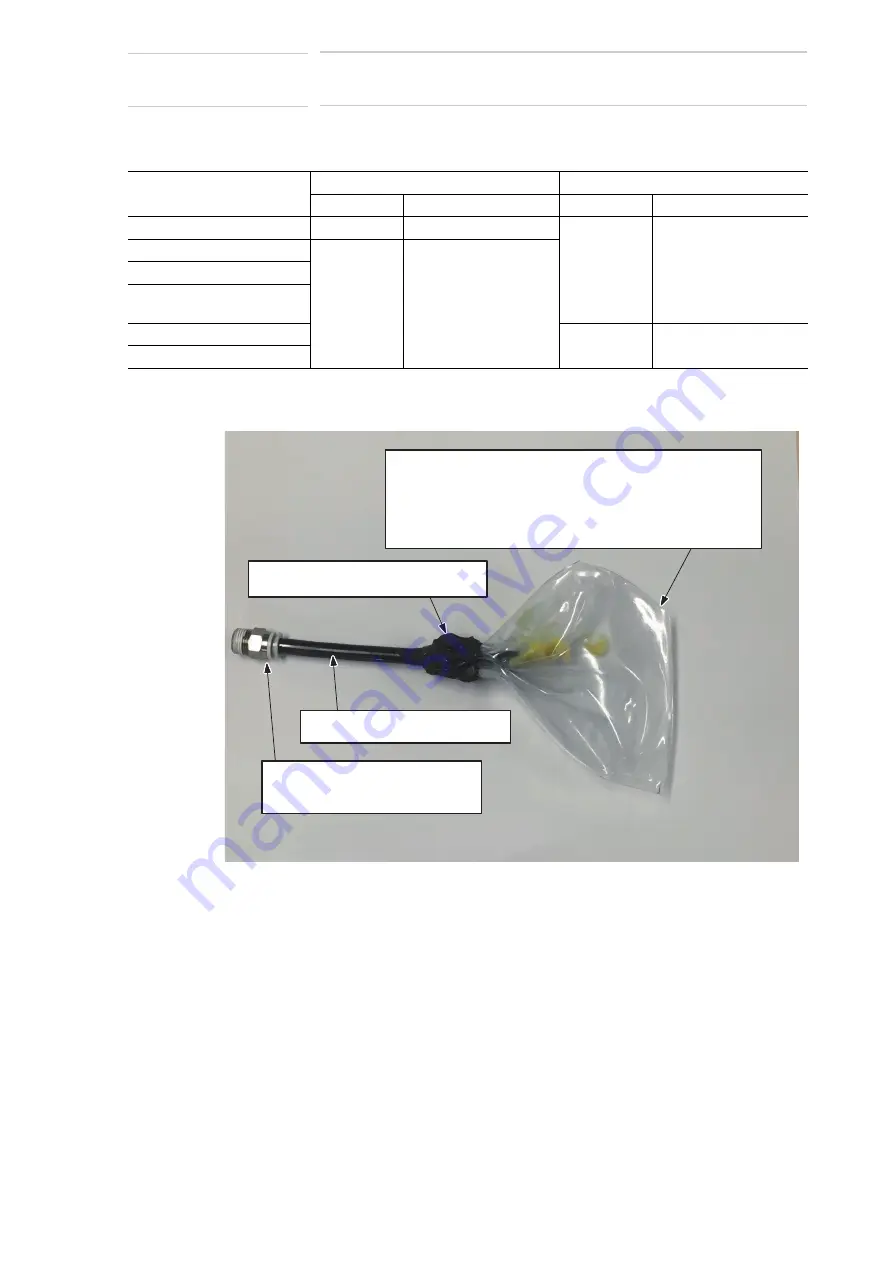

Fig. 9-8: Grease Receiving Bag (Rough Standard)

7. Wipe the discharged grease using a waste cloth. After cleaning and

degreasing the tap part and the thread part of the plug, apply

ThreeBond 1206C to the thread part of the plug. Mount the plug to the

grease exhaust port, and tighten it with the tightening torque indicated

in

table 9-8 “Plug Type and Tightening Torque of Each Axis”

Table 9-8: Plug Type and Tightening Torque of Each Axis

Grease exchanging point

Plug for grease inlet

Plug for grease exhaust port

Plug type

Tightening torque

Plug type

Tightening torque

S-axis

PT1/4

12.0 N•m (1.2 kgf•m)

PT3/8

23 N•m (2.34 kgf•m)

L-axis

PT1/8

4.9 N•m (0.5 kgf•m)

U-axis

R-, B-, and T-gear in the

casing

R-axis

PT1/8

4.9 N•m (0.5 kgf•m)

B- and T-axis

Tube (inside dia.: 6 mm or more)

Grease receiving bag

Bond for fixing a grease receiving bag

Union (inside dia.: 6 mm or more)

PT3/8 or PT1/8

Cut one corner to remove air.

To prevent grease from scattering from the cut corner,

cover the receiving bag with a plastic bag etc. without

being sealed.

74 of 100