9

Maintenance and Inspection

9.4 Gas Maintenance Procedure in the Gas Balancer

9-20

167109-1CD

HW1482308

MS165

6. Discharge gas by slowly releasing the blowdown valve until the gas

pressure is the value shown in

table 9-9 “Adequate Gas Pressure per

Gas Balancer Surface Temperature”

7. Close the needle valve and blowdown valve, and then remove the gas

filling device from the quick connector.

8. Remove the quick connector and mount the cover, then tighten the

hexagon socket head screw plug M6 with flange by using a tightening

torque of 4.9 N•m (0.5 kgf•m).

9. Mount the cover and tighten the hexagon socket head cap screws M4

(length: 6mm) with a tightening torque of 2.8 N•m (0.29 kgf•m.)

10. Turn ON the power supply of the DX200.

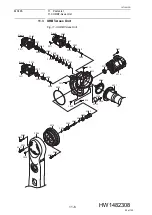

Fig. 9-12: Gas Discharging Operation

9.4.4

Gas Injecting Procedure

9.4.4.1 Necessary Devices

Prepare following devices when injecting gas

• Nitrogen gas cylinder

• Gas filling device: HW1485204

The device includes:

Digital pressure gauge: GC64-173

Quick connector: 10-358-6297

• Thermometer (for measuring the gas balancer surface)

NOTE

After discharging/injecting gas, wait for a few minutes to

stabilize the gas pressure, and then measure the gas pres-

sure.

Cover

㸦

HW1405134-1

㸧

㸧

㸦

Surface temperature measuring point

Gas inlet/gas exhaust port

Enlarged figure

A part

Measure on the surface

of the gas balancer

after removing the cover.

Conical spring washer 2L-4 (2 washers)

Hexagon socket head cap screw M4 (length: 6 mm)(2 screws)

A part

Hexagon socket head screw plug M6

with flange

81 of 100