9

Maintenance and Inspection

9.3 Grease Exchange

9-8

167109-1CD

HW1482308

MS165

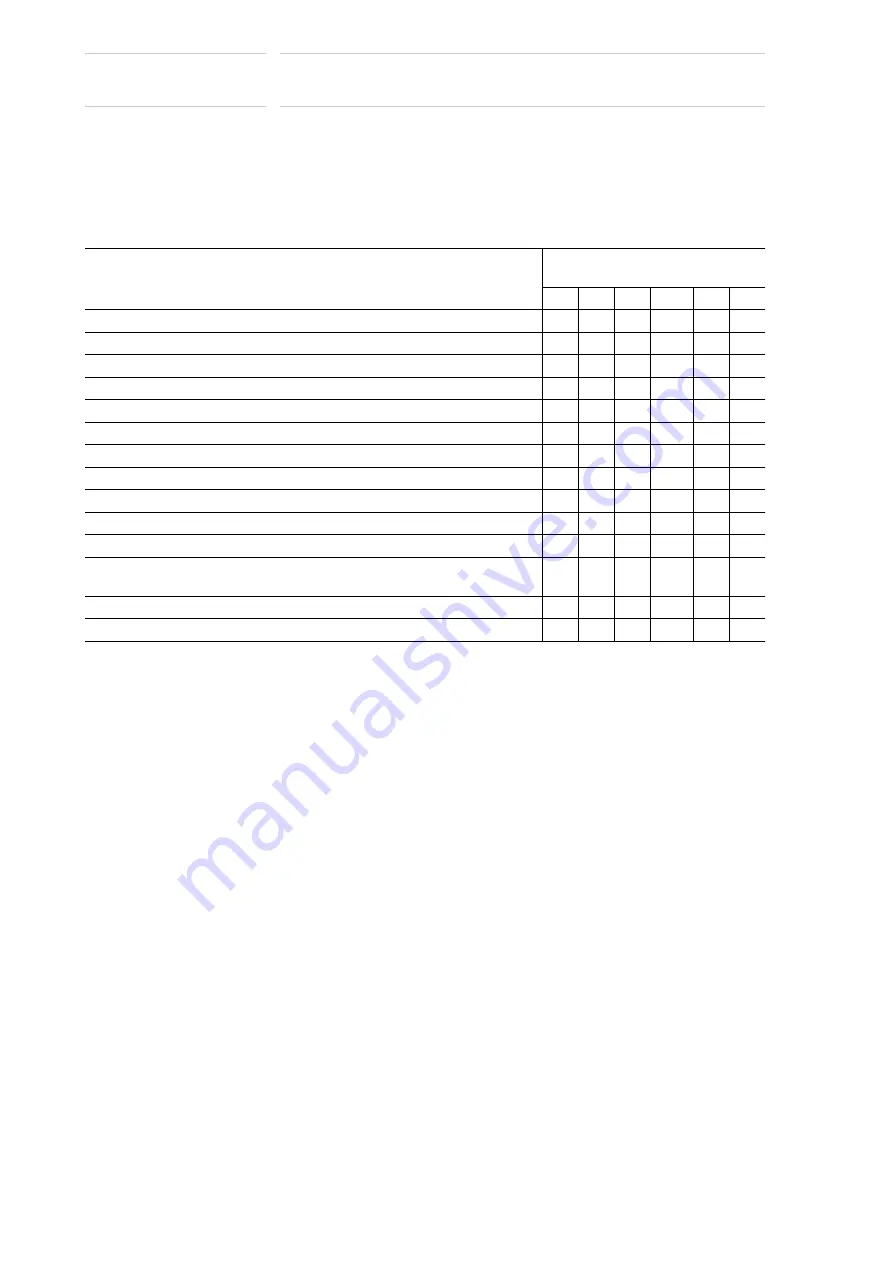

9.3.2 List of Necessary Items

Prepare necessary items as indicated in

. “S”, “L”, “U”, “R”, and “BT” in the table mean axes for grease

exchange to each axis, and “Casing” means R-, B-, and T-gear in a casing

for grease exchange.

9.3.3 Grease Exchange

9.3.3.1 Grease Exchange for S-, L-, U-, R-, B-, and T-Axes Speed Reducer

1. Before injecting/discharging grease, the posture of the manipulator

must be set. Make the posture as indicated in

Posture of Each Axis While Injecting”

to remove the plugs of the

grease inlets and the grease exhausting ports. (Refer to

Position of S- and L-axis Speed Reducer”

U-axis Speed Reducer and R-, B-, and T-gear in a casing”

fig. 9-7 “Plug Position of R-, B-, and T-axis”

.) If it is difficult to make

the recommended posture because of external cabling or etc., adjust

the posture as much as possible to make the position of grease inlet

located in the lower part and the position of exhaust port located in the

upper part. Thus, grease can be filled/exchanged more properly as the

recommended posture.

Table 9-3: List of Necessary Items

Items

When exchanging

the grease of each axis

S

L

U

Casing

R

BT

Grease zerk A-PT1/4

Grease zerk A-PT1/8

Hexagon bit tool, width across flat: 5

Hexagon bit tool, width across flat: 6

Hexagon bit tool, width across flat: 8

Torque wrench (Range of use: 4.9

N•m

- 23

N•m

)

Torque wrench, Extension bar for hexagon bit (30 mm or longer)

ThreeBond 1206C

Recommended grease lubricator: Powerlube P3C by Macnaught

Air supply (air supply pressure: 0.3 MPa or less)

Joint and hose for grease discharging (Approx. 150 mm)

Container for grease discharging (Checking the cubical content (cc) inside

this container should be available.)

Regulator for grease discharging (Recommendation: ARP30-02G by SMC)

Weight scale (Minimum display should be 1 g. Range of use: 0 g - 2,000 g)

69 of 100