9

Maintenance and Inspection

9.4 Gas Maintenance Procedure in the Gas Balancer

9-18

167109-1CD

HW1482308

MS165

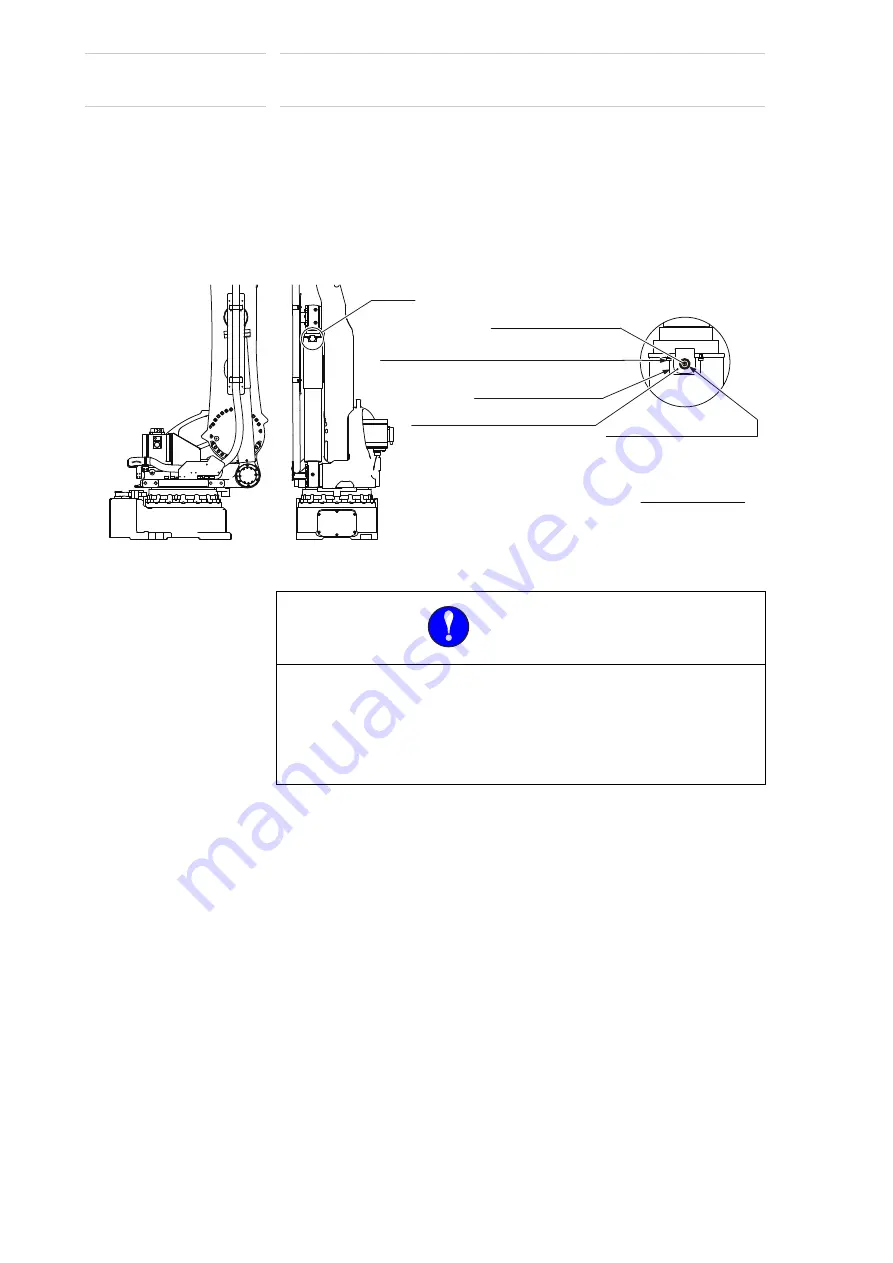

7. Remove the quick connector and mount the cover, then tighten the

hexagon socket head screw plug M6 with flange by using a tightening

torque of 4.9 N•m (0.5 kgf•m).

8. Mount the cover and tighten the hexagon socket head cap screws M4

(length: 6mm) with a tightening torque of 2.8 N•m (0.29 kgf•m.)

9. Turn ON the power supply of the DX200.

Fig. 9-11: Gas in Gas Balancer Pressure Inspection

9.4.3

Gas Discharging Procedure

9.4.3.1 Necessary Devices

Prepare following devices when discharging gas

• Gas filling device: HW1485204

The device includes:

Digital pressure gauge: GC64-173

Quick connector: 10-358-6297

Valve of the service gauge: SS-1KS4

• Thermometer (for measuring the gas balancer surface)

MANDATORY

•

Discharge all gas from the gas balancer when in the following

cases.

– When dismounting the gas balancer from the manipulator.

– When air-flight the gas balancer.

(It is treated as a hazardous material when the gas balancer is

air-flight with gas filled.)

Cover

㸦

HW1405134-1

㸧

㸧

㸦

Surface temperature measuring point

Gas inlet/gas exhaust port

Enlarged figure

A part

Measure on the surface

of the gas balancer

after removing the cover.

Conical spring washer 2L-4 (2 washers)

Hexagon socket head cap screw M4 (length: 6 mm)(2 screws)

A part

Hexagon socket head screw plug M6

with flange

79 of 100