1.5 Motoman Safety

6

1.5.3

Work Area Safety

Carelessness contributes to serious accidents in the

work area. To ensure safety, enforce the following

precautions:

1.5.4

Operation Safety

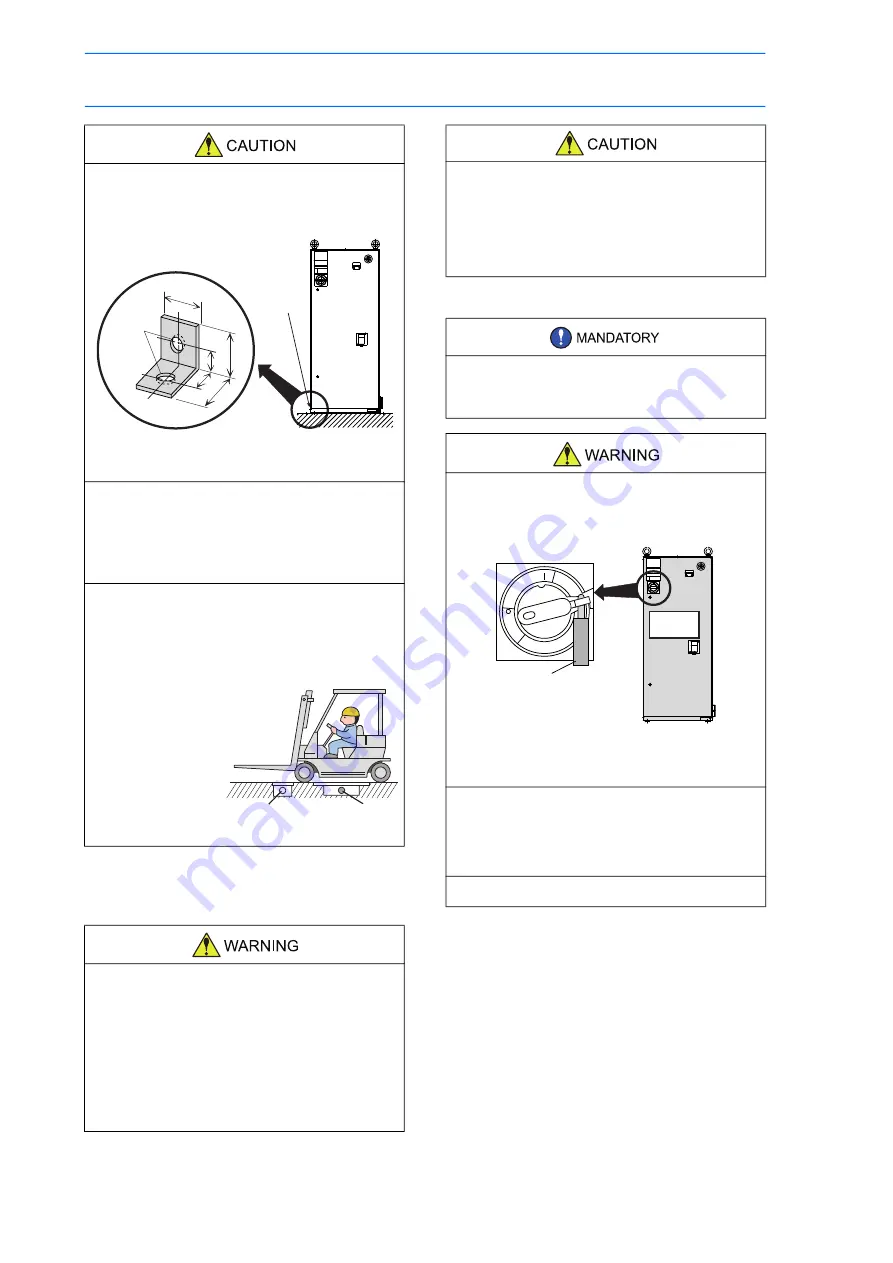

• Secure the position of the NX100 after

setting up.

Attach the NX100 to the floor or rack, etc., using the

screw holes on the bottom of the NX100.

Failure to observe this caution could lead to injury

or equipment damage if the NX100 should shift or

fall.

• Be familiar with the connection diagram

before wiring the NX100, and perform the

wiring in accordance with the connection

diagram.

There is a danger of equipment damage or injury

due to mis-wiring and unexpected movement of the

equipment.

• Take precautions when wiring and piping

between the NX100, manipulator, and

peripheral equipment. Run the piping,

wiring, or cables through a pit or use a

protective cover, so that they are not

stepped on by personnel or run over by

the forklift.

• Install a safeguarding around the

manipulator to prevent any accidental

contact with the manipulator while the

power is on. Post a warning sign stating

“Off-limits During Operation” at the

entrance of the enclosure. The gate of

the safeguarding must be equipped with a

safety interlock. Be sure the interlock

operates correctly before use.

Failure to observe this caution may result in a

serious accident due to contact with the

manipulator.

40

30

50

30

50

(mm)

NX100

Tapped Holes for

M10 Screws on

the NX100 Side

12 mm

diameter

2 holes

Operators and other

personnel may

stumble on exposed

wiring or piping.

Cable damage can

cause unexpected

manipulator motion

resulting in injury or

property damage.

SAFETY

FIRST

Piping

Cable Channel

lead

• Store tools and similar equipment in

proper locations outside of the enclosure.

Tools and loose equipment should not be left on the

floor around the manipulator, NX100, or welding

fixture, etc., as damage to equipment can occur if

the manipulator comes in contact with objects or

equipment left in the work area, or injury may result

in if the hit objects jump toward you.

• Persons operating or inspecting the

manipulator should be trained as required

by applicable laws and company policies.

(Refer to section 1.2 Special Training)

• When attaching a tool such as the welding

torch to the manipulator, be sure the

power supply of the NX100 and the tool is

off, lock the switch, and display a

warning sign.

Turning the power on during tool installation may

case electric shock or injury due to unexpected

movement of the manipulator.

• Never exceed the rated capacity of the

manipulator (capacity can be found in the

specifications section of the manipulator

manual.)

Failure to observe this caution may result in injury or

damage to equipment.

• Teach jobs from outside the manipulator's

work area whenever possible.

NX100

TRIPPED

ON

OFF

RESET

PADLOCK

ENERGING

PROHIBITED