1.1 For Your Safety

2

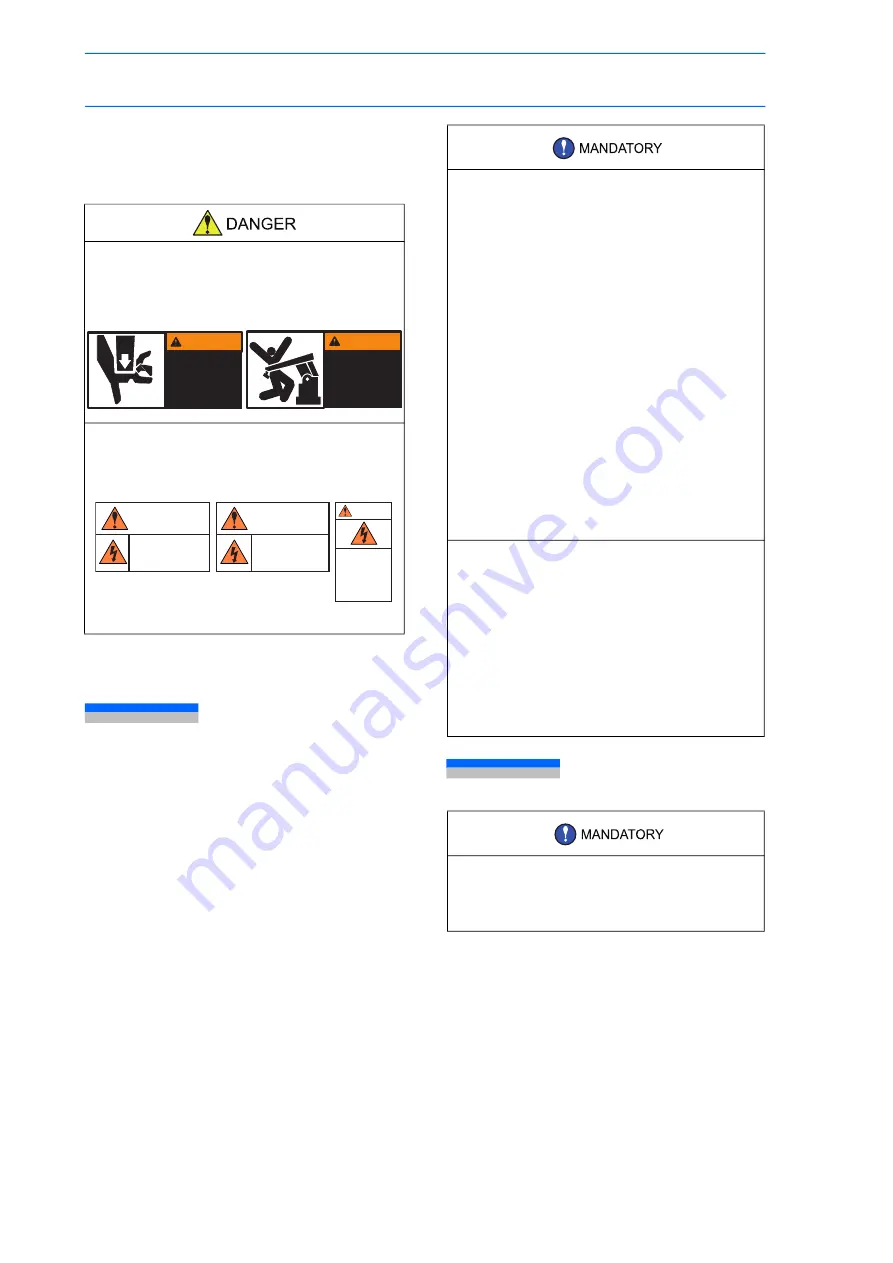

Explanation of Warning Labels

The following warning labels are attached to the

manipulator and NX100.

Fully comply with the precautions on the warning

labels.

1

Safety

1.1

For Your Safety

Robots generally have requirements which are different

from other manufacturing equipment, such as larger

working areas, high-speed operation, rapid arm

movements, etc., which can pose safety hazards.

Read and understand the instruction manuals and

related documents, and observe all precautions in

order to avoid the risk of injury to personnel and

damage to equipment.

It is the user's responsibility to ensure that all local,

state, and national codes, regulations rules, or laws

relating to safety and safe operating conditions are met

and followed.

1.2

Special Training

• The label described below is attached to

the manipulator.

Observe the precautions on the warning labels.

Failure to observe this caution may result in injury or

damage to equipment.

• The following warning labels are attached

to NX100.

Observe the precautions on the warning labels.

Failure to observe this warning may result in injury

or damage to equipment.

Refer to the NX100 INSTRUCTIONS for the

warning label location.

WARNING

Do not enter

robot

work area.

WARNING

Moving parts

may cause

injury

WARNING

WARNING

High Voltage

Do not open the door

with power ON.

High Voltage

Do not ope the cover.

WARNING

May cause

electric shock.

Ground the earth

terminal based on

local and national

electric code.

• Teaching maintenance of the robot must

conform to:

-Industrial Safety and Health Law

-Enforcement Order of Industrial Safety

and Health Law

-Ordinance of Industrial Safety and

Health Law

Other related laws are:

-Occupational Safety and Health Act in

USA

-Factory Act (Gewerbeordnung) in

Germany

-Health and Safety at Work, etc. Act in UK

-EC Directive 89/392 Machinery and 91/

368 EEC

• Prepare

-SAFETY WORK REGULATIONS

based on concrete policies for safety management

complying with related laws.

• Observe the

-MANIPULATING INDUSTRIAL ROBOTS-

SAFETY (ISO 10218)

for safe operation of the robot. (Japan Only) (JIS B

8433)

• Reinforce the

-SAFETY MANAGEMENT SYSTEM

by designating authorized workers and safety

managers, as well as giving continuing safety

education.

• Teaching and maintaining the robot are

specified as "Hazardous Operations" in

the Industrial Safety and Health Law

(Japan only).

Workers employed in these above operations are

requested to attend special training offered by

YASKAWA.

• Persons who teach or inspect the

manipulator must undergo required

training before using the manipulator.

• For more information on training, inquire

at the nearest YASKAWA branch office.