10

Disassembly and Reassembly of Balancer Unit

10.2 Disassembly and Reassembly of Balancer Unit

10-2

HW1485471

HW1485471

10.2

Disassembly and Reassembly of Balancer Unit

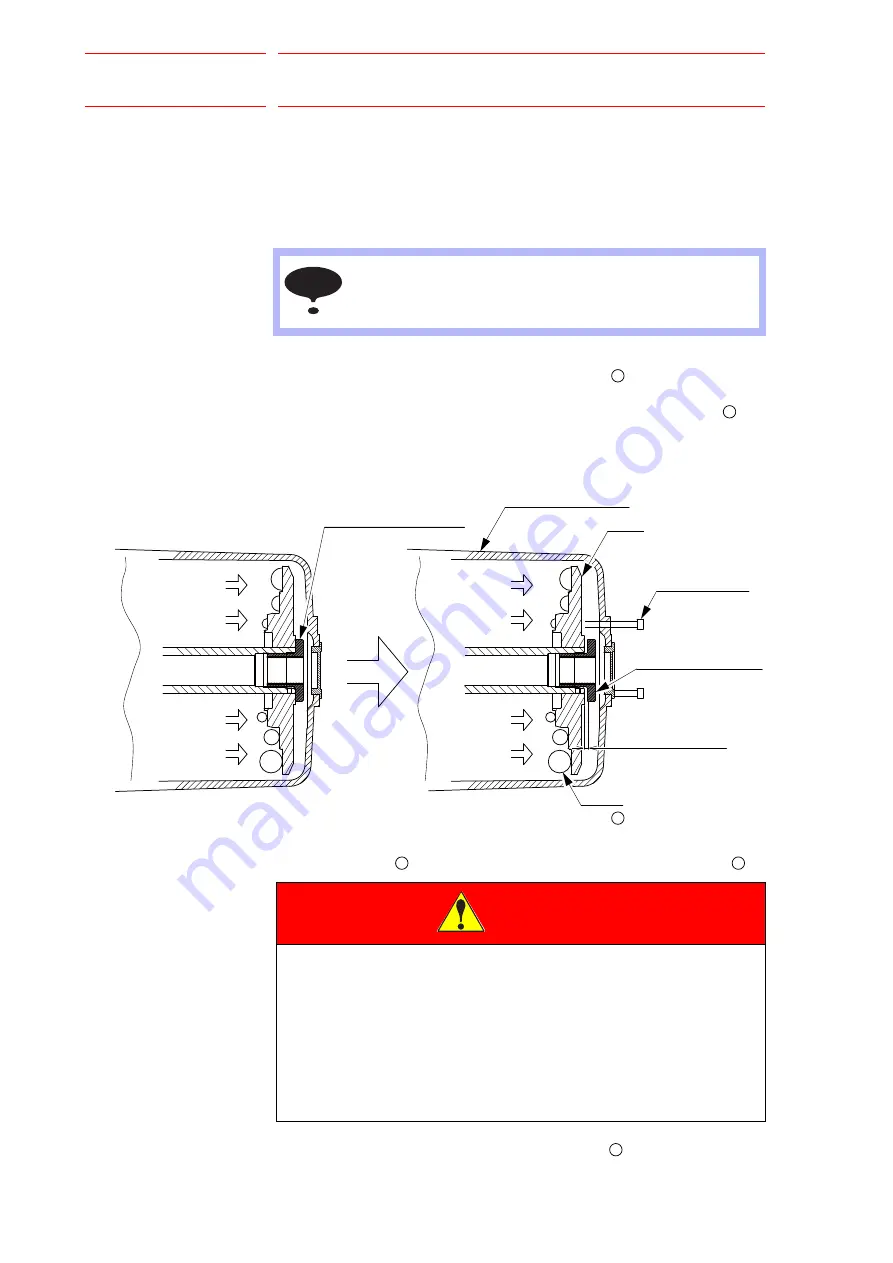

• Refer to

fig. 10-2 “Spring Fixing Bolts Mounted”

.

Disassembly

1. Make the L-arm of the manipulator vertical to the ground.

2. Remove the hexagon socket head cap screws

and mount 3 spring

fixing bolts M8 or M10 instead. Push up 3 points evenly about 5 mm of

the flange which is located inside of the balancer unit assembly

so

that the spring force is not applied to the rod of the balancer unit

assembly.

Fig. 10-2: Spring Fixing Bolts Mounted

3. Remove the hexagon socket head cap screws

.

4. Mount fully threaded screws M12 for removal on the shaft assembly

(knuckle part)

, then remove the shaft assembly (knuckle part)

.

5. In order to prevent the balancer unit assembly

from falling, support

it by using a chain block, etc.

NOTE

Although the balancer unit position would not deviate when

disassembled and reassembled, refer to

before replacement just in case.

5

1

Space (approx. 5 mm)

Rod

(free from spring force)

Flange

Balancer unit assembly

Spring fixing bolt

Spring pressure

direction

Spring

Spring pressure

direction

Rod (spring force applied)

Spring pressure

direction

Spring pressure

direction

DANGER

•

Be sure to mount the spring fixing bolts when removing the balancer

unit from the manipulator. If the balancer is removed without the

spring fixing bolts, the rod will rapidly shrink which may result in

injury or accident.

•

Before removing the balancer unit from the manipulator, confirm

that the L-axis motor brake is appropriately functioning and L-axis is

firmly secured with a chain block, etc., to prevent it from rotating.

Failure to observe this instruction may rotate the L-axis and cause a

hazardous condition.

6

2

2

1

104/134