5

Notes on Grease Replenishment/Exchange Procedures

5.1

Grease Exchange Procedures for Each Axis Speed Reducer

5-5

HW1485471

HW1485471

5. Injection stop:

– <When replacing the speed reducer>

Stop injecting grease when grease can be seen from the exhaust

port.

– <When exchanging grease>

The old grease is discharged from the grease exhaust port. At this

time, stop injection when the mixture of the old grease and the new

grease in an equal ratio is seen.

And then, skip the steps 6 and 7, and proceed to the step 8.

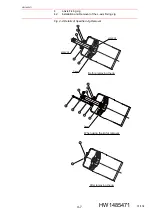

6. Operate each axis about 5 times in the teach mode as shown in

table 5-3 “Teaching Operation for Each Axis”

.

7. Inject grease again, and when grease comes out from the exhaust

port, grease injection is completed.

8. Discharge the specified amount of grease from the grease inlet or

grease exhaust port. (Refer to

.) In order to discharge the specified

amount of grease, receive the discharged grease into a container, and

then measure the weight of the discharged grease by weighing the

container till the amount reaches to the specified amount.

Use one of the following methods to discharge grease.

Method 1: Extruding grease by air

(1) Connect the joint and the hose to the grease inlet.

(2) Connect the regulator to the grease exhaust port.

(3) Inject air from the grease exhaust port to extrude grease by air.

(Extrusion air pressure: 0.025 MPa or less)

(4) If grease is not discharged enough by injecting air, operate the

manipulator about 5 times in the teach mode as shown in

.

Table 5-3: Teaching Operation for Each Axis

Axis to replenish

grease

Angle for teaching

operation

Speed for teaching

operation

S-axis

S-axis ±45°

User-specified

L-axis

L-axis ±45°

U-axis

U-axis ±45°

In the casing

R-, B-, and T-axis gear

R-, B-, and T-axes

R-axis ±90°

B-axis ±45°

T-axis ±90°

37/134