9 Maintenance and Inspection

9.1 Inspection Schedule

9-3

155492-1CD

HW0484820

SDA20

*1

Wire harnesses in the arm & rotation axis are to be replaced at 24000 H inspection.

*2

For the grease, refer to

Table 9-2 "Inspection Parts and Grease Used"

*3

When a grease leakage is found, promptly contact your Yaskawa representative.

4

Actuator

Visual

Check for grease

leakage.

*3

Grease

Gun

Check for malfunction.

(Replace if necessary.)

For S-, L-, 7th-, U-axis:

Exchange grease

*2

(6000H cycle)

For R-, B-, T-axis:

Replenish grease

*2

(6000H cycle).

5

Baseplate

mounting

bolts

Spanner,

Wrench

Tighten loose bolts.

Replace if necessary.

6

Cover

mounting

screws

Screw-

driver,

Wrench

Tighten loose screws.

Replace if necessary.

7

Connector

base

Manual

Check for loose

connectors and tighten if

necessary.

8

Wire

harness in

arm

Visual

Check for damages.

Replace

*1

9

Wire

harness in

manipulator

(Lead wires

for rotation-

axis)

Visual

Check for damages.

Replace

*1

10

Battery pack

in manipula-

tor

Replace the battery pack

when the battery alarm

occurs or the manipulator

has been driven for

36000H.

11

Overhaul

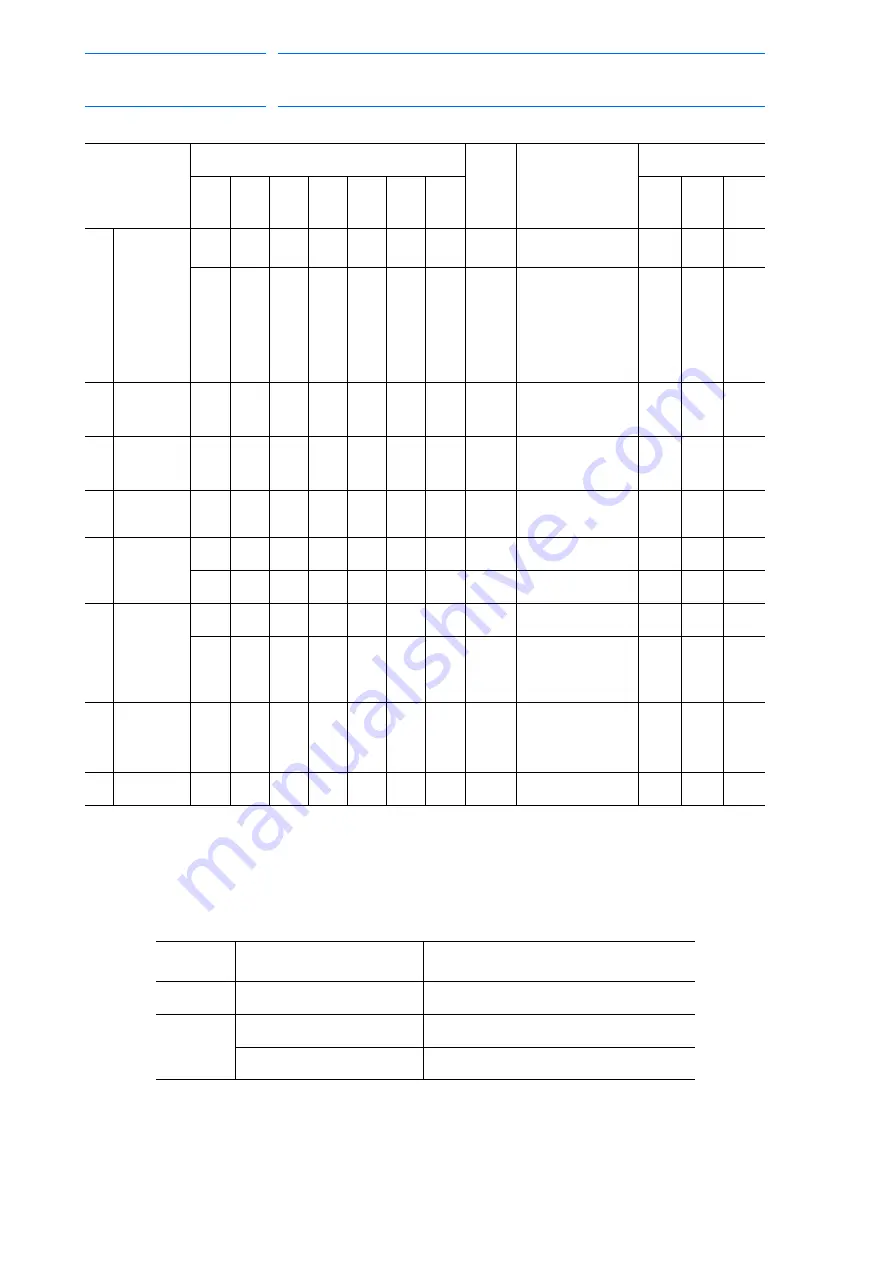

Table 9-2: Inspection Parts and Grease Used

No.

Grease Used

Inspected Parts

3

Molywhite RE No. 00

Speed reducer for the rotation-axis

4

Unilite FS No.0

S-, L-, 7th-, U-axis actuator

Harmonic Grease SK-1A

R-, B-, T-axis actuator

Table 9-1: Inspection Items

Items

Schedule

Method

Operation

Inspection Charge

Daily

1000

H

Cycle

3000

H

Cycle

6000

H

Cycle

12000

H

Cycle

24000

H

36000

H

Specified

Personnel

Licensee

Service

Company

46 of 66