9 Maintenance and Inspection

9.3 Notes on Grease Replenishment/Exchange Procedures

9-17

155556-1CD

HW0484963

VA1400

9.3.6 Grease Replenishment for B-Axis Speed Reducer

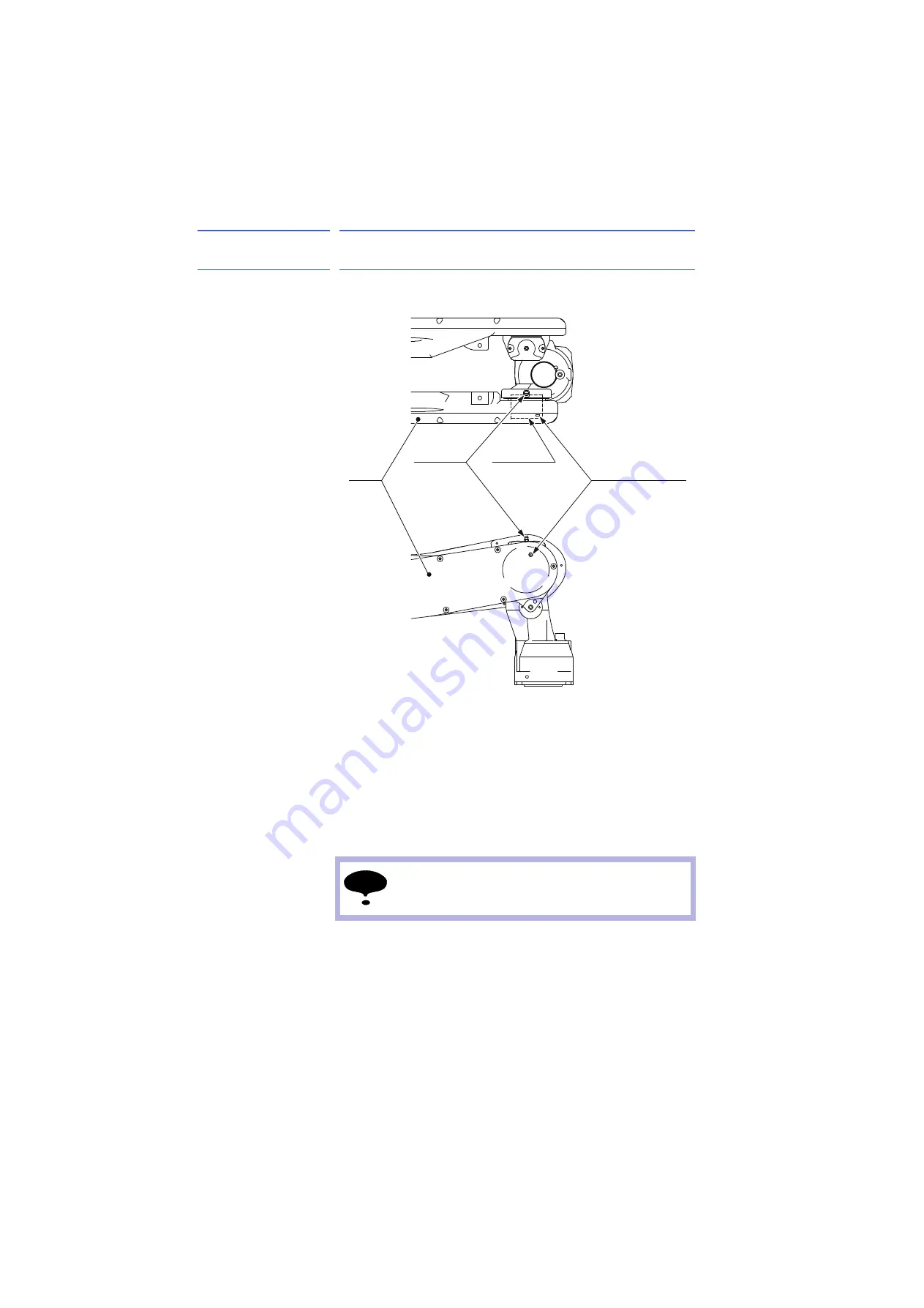

Fig. 9-9: B-Axis Speed Reducers Diagram

1. Remove the plug LPM5 from the exhaust port.

2. Remove the hexagon socket head cap screw M6 from the grease inlet.

3. Install a grease zerk A-MT6X1 to the grease inlet. (The grease zerk is

delivered with the manipulator.)

4. Remove the cover, then inject grease through the grease inlet using a

grease gun. (Refer to

Fig. 9-9 “B-Axis Speed Reducers Diagram”

– Grease type:

Harmonic grease SK-1A

– Amount of grease:

7 cc (14 cc for the 1st supply)

5. Remove the grease zerk from the grease inlet, and reinstall the screw.

Before installing the screw, apply Three Bond 1206C on the thread

part of the screw, then tighten the screw with a tightening torque of

6 N•m (0.6 kgf•m).

6. Reinstall the plug to the exhaust port, then reinstall the cover.

NOTE

The exhaust port is used for air exhaust, and the grease is

not exhausted from the exhaust port. Do not inject

excessive grease through the grease inlet.

Cover

(Plug LPM5)

Exhaust port

B-axis speed

reducer

Grease inlet

Hexagon socket head

cap screw M6

62 of 85