10-1

10

10

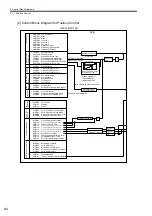

Absolute Position Detection

This chapter explains an absolute position detection system that uses an abso-

lute encoder. Be sure to read this chapter carefully when using a Servomotor

equipped with an absolute encoder.

10.1 Structure of the Absolute Position Detection Function - - - - 10-2

10.1.1 Outline of the Function - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 10-2

10.1.2 Basic Terminology - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 10-2

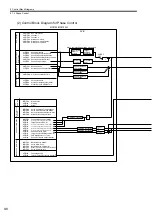

10.2 Startup the Absolute Position Detection Function - - - - - - - 10-3

10.2.1 System Startup Procedure - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 10-3

10.2.2 Setting Related Parameters - - - - - - - - - - - - - - - - - - - - - - - - - - - - 10-4

10.2.3 Initializing the Absolute Encoder - - - - - - - - - - - - - - - - - - - - - - - - - 10-7

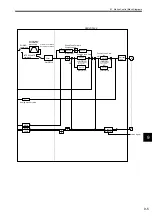

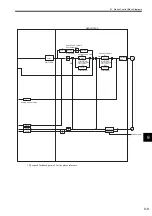

10.3 Using an Absolute Encoder - - - - - - - - - - - - - - - - - - - - - 10-12

10.3.1 Finite Length Axis - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 10-12

10.3.2 Infinite Length Axis - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 10-15