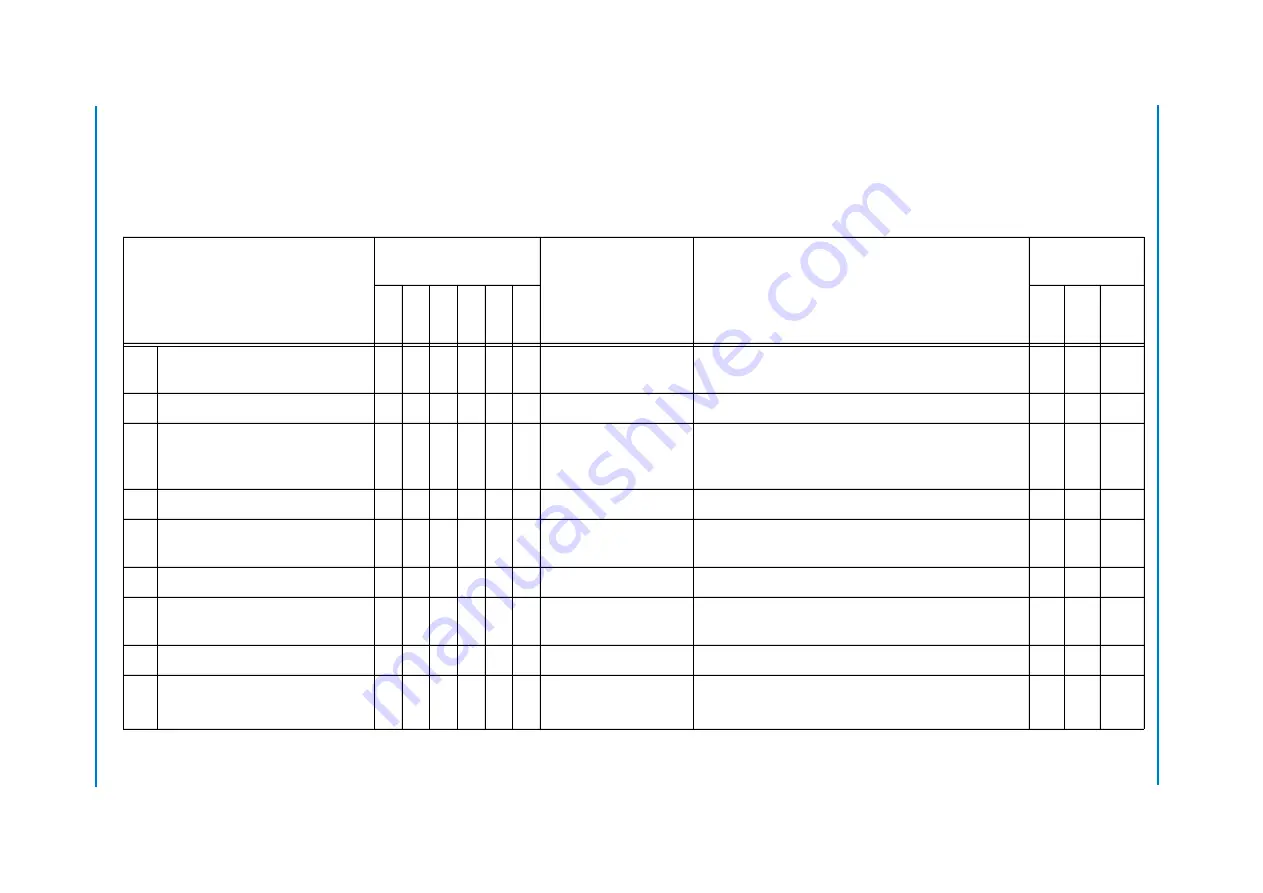

Maintenance and inspection

9 - 50

1

Trained staff

2

YASKAWA trained staff

3

YASKAWA staff

Inspection intervals

Item numbers

1

Schedule (h)

Checking method

Operation

Inspection

Charge:

Daily

1000

5000

9000

18000

36000

1

2

3

1

Alignment marks

Visual inspection

Check alignment mark accordance and damage

at the home position.

2

External cable

Visual inspection

Check cable for damage.

3

Working area and robot

Visual inspection

Dirty working area has to be cleaned. Please

control the robot for damage and external

cracks.

4

Motors for L and U-axes

Visual inspection

Check for grease leakage

2

.

5

Fastening bolts of baseplate

Using correspond-

ing tool

Tighten loose screws (replace if necessary).

6

Power input module

Manual

Check for loose connectors

7

L-, and U-axes motor connec-

tion

Manual

Check for loose plug connections (tighten if nec-

essary).

8

Connection in S-head

Manual

Check for loose connectors

9

L-axis balancer

Grease gun

Visual inspection

Supply grease. Tighten loose screws (replace if

necessary).

Summary of Contents for MPL160-J00

Page 1: ...ROBOTICS MPL160 J00 YR MPL0160 J00 Operating and Maintenance Manual...

Page 36: ...Technical data 6 36 6 5 1 2 Stop position L axis 100 deflection deg deg s deg s sec...

Page 37: ...Technical data 6 37 6 5 1 3 Stop position U axis 100 deflection deg deg s deg s sec...

Page 61: ...Maintenance and inspection 9 61 Air outlet cap Joint 80 9 0 170 1 1 2 2 2 1 2...

Page 91: ...Parts lists 11 91...