Maintenance and inspection

9

-

51

10

Wire harness in the robot

Visual, multimeter

Check for conduction between the main connec-

tor of base and intermediate connector with

manually shaking the wire. Check the protection

spring

3

.

Replace

4

11

Link unit

Visual inspection

Move L- and U-axes back and forward and also

up and down to check any backlash. Refill

grease (see chapter 9.3.3 "Refilling the amount

of grease in joints" on page 63).

12

Battery unit in robot

If a battery alarm appears or after the robot has

been operated for 36,000 hours, the battery

must be replaced.

13

S-, L-, U- and T-axes gear

Grease gun

Check for faults (replace if necessary). The

grease

5

has to be refilled every 5,000 hours or

replaced every 9,000 hours (see chapter 9.3.1

"Grease filling the main axes" on page 60 and

9.3.2 "Grease filling the wrist axes"on page 62).

14

Bearing

Grease gun

The grease

5

must be replaced every 5,000

hours or every year. After what occurs first

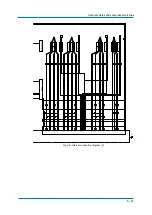

Inspection intervals

Item numbers

1

Schedule (h)

Checking method

Operation

Inspection

Charge:

Daily

1000

5000

9000

18000

36000

1

2

3

Summary of Contents for MPL160-J00

Page 1: ...ROBOTICS MPL160 J00 YR MPL0160 J00 Operating and Maintenance Manual...

Page 36: ...Technical data 6 36 6 5 1 2 Stop position L axis 100 deflection deg deg s deg s sec...

Page 37: ...Technical data 6 37 6 5 1 3 Stop position U axis 100 deflection deg deg s deg s sec...

Page 61: ...Maintenance and inspection 9 61 Air outlet cap Joint 80 9 0 170 1 1 2 2 2 1 2...

Page 91: ...Parts lists 11 91...