Technical data

6

-

34

6.5

Stopping Angle and Time at the Emergency Stop

The definition of the coastdown times is important for determining the safety distance for

protective devices. The overrun time is the time that elapses from the point of time when

the stop signal is triggered until the robot comes to a complete stop. The overrun distance

is the angle that the robot travels from the point of time when the stop signal is triggered

until the robot comes to a complete stop.

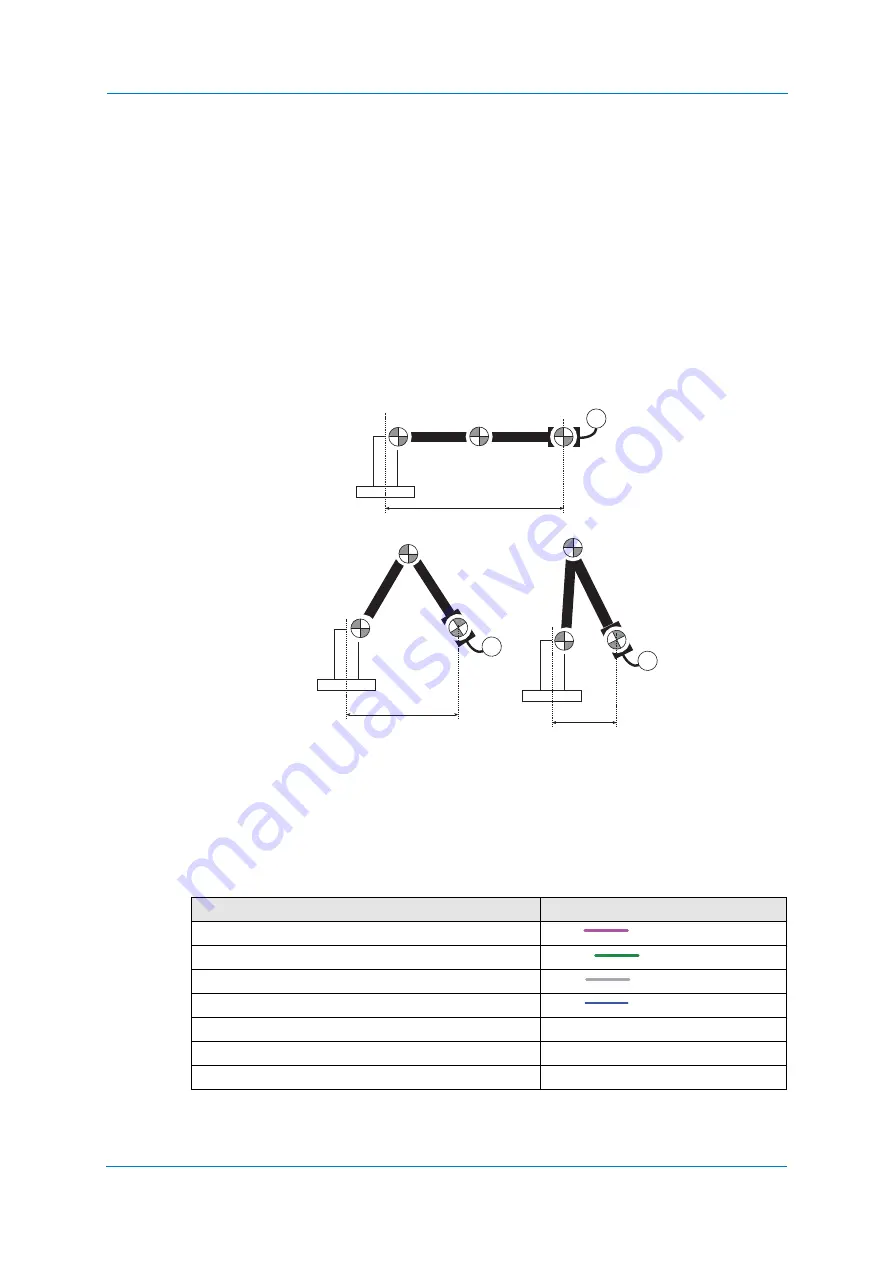

The following diagrams show only the values for the S, L, and U axes since these axes have

the largest deflection. For a safety stop with stop category 0, the mean values determined

through testing and simulation are specified.

The actual overrun distances and overrun times may differ due to internal and external

influence on the braking torque. According to the mode, robot application, and number of

triggered safety stops with stop category 0, a different brake wear may occur. We

recommend that the coastdown path be checked once a year.

Fig. 6-7: Main axes at 100%, 66%, and 33% deflection

In Fig. 6-7: "Main axes at 100%, 66%, and 33% deflection" the S, L, and U axes are shown

at 33%, 66%, and 100% deflection according to DIN EN ISO 10218-1.

In these three positions, the coastdown paths and coastdown times were determined during

a safety stop with stop category 0 and stop category 1. In the following diagrams, they are

specified at payloads of 33%, 66%, and 100%.

The pertinent legend can be found in the following table:

Definitions

Description

Load 100%

pink

Load 66%

green

Load 33%

gray

Load 100%

blue

Overrun distance degrees°

[deg]

Overrun time second

[sec]

Robot speed degrees°/second

[deg/s]

33%

66%

100%

Summary of Contents for MPL500-J00

Page 1: ...ROBOTICS MPL500 J00 YR MPL0500 J00 Operating and Maintenance Manual ...

Page 36: ...Technical data 6 36 6 5 1 2 Stop position L axis 100 deflection ...

Page 37: ...Technical data 6 37 6 5 1 3 Stop position U axis 100 deflection ...

Page 61: ...Maintenance and inspection 9 61 Air outlet cap Joint 80 9 0 170 1 1 2 2 2 1 2 ...