Maintenance and inspection

9

-

59

1. Remove plug from grease exhaust port (OUT) and grease inlet (IN) port.

2. Mount the lubricating nipple to the grease inlet opening.

3. Press the grease into the grease inlet opening using a grease gun.

4. To squeeze out the excess fat, all taxes must be brought to operating temperature.

•

In a operating JOB or a special moving JOBs (about 20 minutes at 100% speed).

5. Wipe away excess grease with a cloth.

6. Remove the lubricating nipple from the grease inlet opening and mount the plug again.

Before mounting the plug, apply to thread part.

Tightening torque of sealing plug

Designation

Tightening torque (Nm)

PT 3/8

23

PT 1/4

12

PT 1/8

5

PT 1/16

4

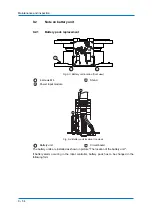

Example:

Summary of Contents for MPL500-J00

Page 1: ...ROBOTICS MPL500 J00 YR MPL0500 J00 Operating and Maintenance Manual ...

Page 36: ...Technical data 6 36 6 5 1 2 Stop position L axis 100 deflection ...

Page 37: ...Technical data 6 37 6 5 1 3 Stop position U axis 100 deflection ...

Page 61: ...Maintenance and inspection 9 61 Air outlet cap Joint 80 9 0 170 1 1 2 2 2 1 2 ...