6-23

166006-1CD

166006-1CD

6

Maintenance and Inspection

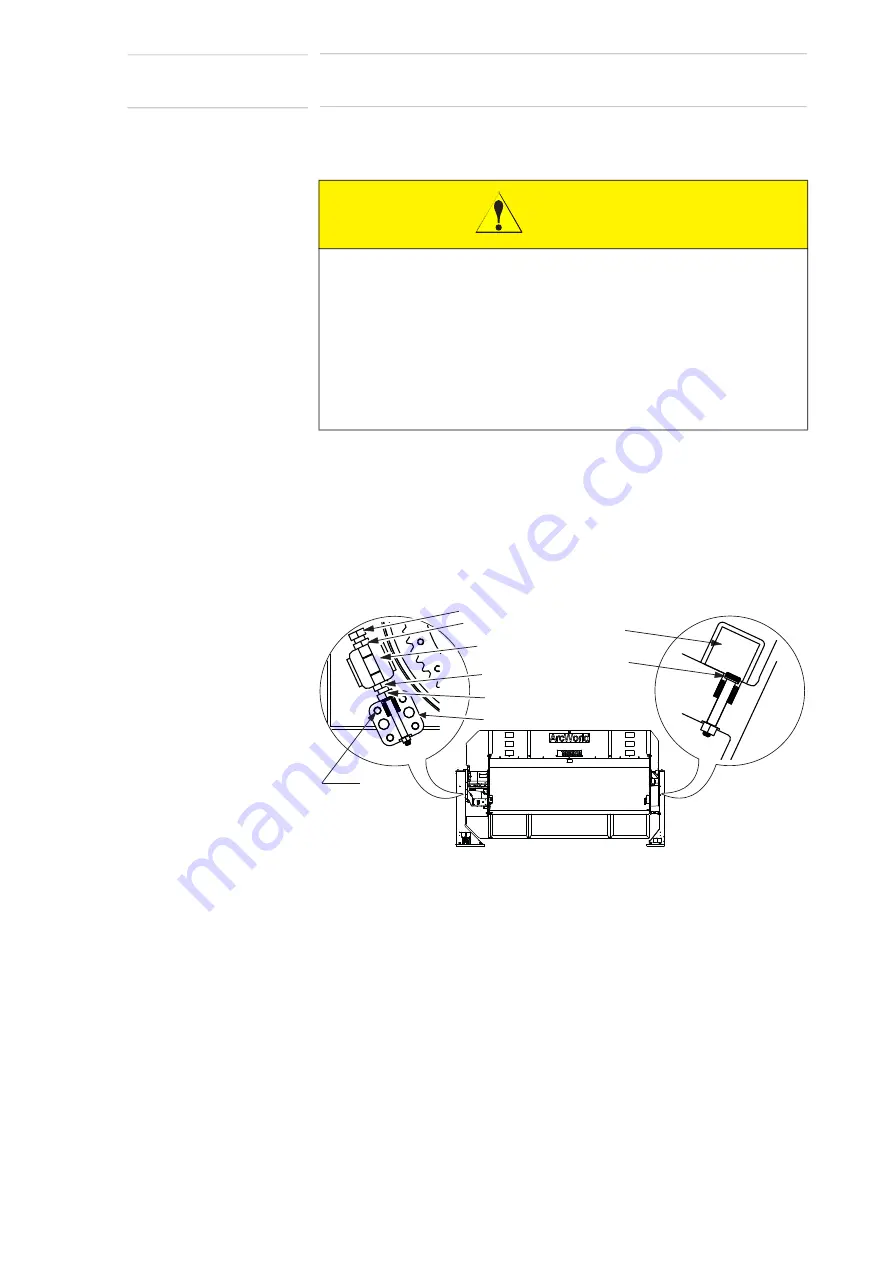

6.12 Positioner Home Position

RM2-755/1255SL

Positioner

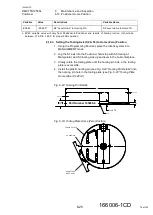

6.12.2 RM2-1255 Headstock

6.12.2.1 Setting the Main Axis (S1) to Home (Zero) Position

1. With the machine at operating temperature, loosen the jam nuts on the

headstock hardstop adjustment screw.

2. Back the adjustment screws out so the Positioner only touches the

tailstock hardstop.

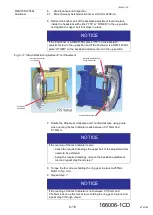

Fig. 6

-

21: Locating Stopping Block with Shock Absorber

3. Using the Programming Pendant, place the robotic system into

“MANAGEMENT” mode.

4. Jog S1 axis into Positioner hardstop with B-side at Manipulator.

Increment Positioner against hard stop at the tailstock side until the

holding torque is 20%.

5. Press the [TOP MENU] key on the programming pendant.

6. Cursor to {ROBOT} and press [SELECT].

7. Cursor to {HOME POSITION} and press [SELECT].

8. Press the [PAGE OVER] key to {S1} (indicated in top right corner of

Programming Pendant display panel).

9. Press [SELECT].

10. Cursor to {YES}, and press [SELECT].

CAUTION

• Make sure the machine is operating temperature before setting the

Main Axis (S1) to the Home (Zero) position.

If machine is not warm torque values will increase which will cause

inaccurate hardstop settings. Two ways to reach the operating

temperature are:

– Run the machine for some time.

– Leave the servos on by pressing the hold button on the teach

pendant.

STOP BLOCK

PLUNGER

BOLT

RM2 -1255SL

HEADSTOCK HARD STOP

RM2-755 & 1255 SL

TAILSTOCK STOPS

PLATE GEAR

STOP BLOCK

JAM NUT

JAM NUT

ADJUSTMENT SCREW

ADJUSTMENT SCREW

MAIN DRIVE HARD STOP

CONICAL

SPRINGS AND

ADJUSTMENT

SCREWS

74 of 145