6-2

183523-1CD

183523-1CD

6

Maintenance and Troubleshooting

6.1 Inspection Interval

RM2-755-RDR Postioner

6.1 Inspection Interval

Proper inspections are essential not only to assure that the mechanism

will be able to function for a long period, but also to prevent malfunctions

and assure safe operation.

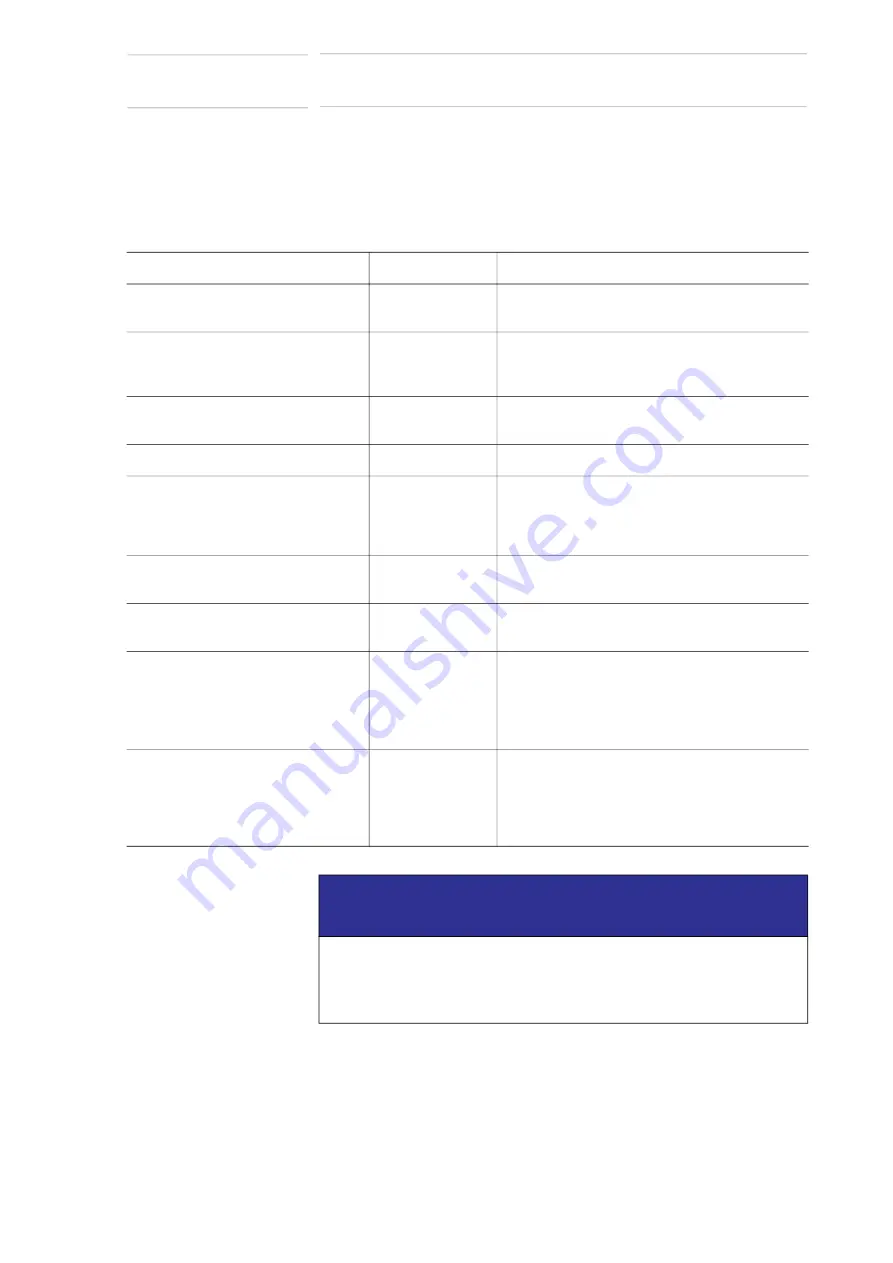

Table 6

-

1: Periodic Maintenance for Positioner

Inspection Item

Frequency

Inspection Operation

Physical damage

Daily

Check for physical damage; this indicates a load

collision and is evidence of misuse.

Excessive or unusual noise

Daily

Listen for grinding, excessive or irregular noise.

Contact Customer Support. Refer to

“Customer Support Information” on page 1-5

Weld Brushes

Weekly

Check for dirt and ensure full contact with

faceplate.

Cleaning

As required

Clean with dry cloth or compressed air.

Positioner Axis Motor Connectors

•

1,000 H

•

6,000 H

•

12,000 H

Check for loose connections. tighten if necessary.

Positioner Tooling Axis Speed

Reducer

12,000 H

Grease with YASKAWA P/N 132412-1,

Molywhite RE00

Positioner Main Axis Speed Reducer

20,000 H

Grease with YASKAWA P/N 132412, Moly-White

RE00

Tailstock Main Sweep Axis Bearing

Monthly

Grease with YASKAWA P/N 180144-1,

Mobil CM-P, Lithium Complex. Apply grease with

a grease gun thru the two grease fittings on each

side. Apply five squeezes of the grease gun lever

(approximately 2@ 1.25g x 5).

Motomount Bearing

Monthly

Grease with YASKAWA P/N 180144-1, Mobil

CM-P, Lithium Complex. Apply grease with a

grease gun thru the grease fitting. Apply 10

squeezes of the grease gun lever (approximately

1.25g x 10).

NOTICE

The inspection interval depends on the total servo operation time.

For axes which are used very frequently other than arc welding, it is

recommended that inspections be conducted at shorter intervals.

Contact Customer Support.

46 of 104