1-3

183523-1CD

183523-1CD

1

Introduction

1.2 System Overview

RM2-755-RDR Postioner

A tooling plate multiple angle control feature allows the programmer to

define the angle of the tooling presented to the operator (with a resolution

of infinite degrees). This improves load station ergonomics and part

tacking (see

).

Fig. 1

-

2: Tooling (Orbital) Axis “S” — Tooling Plate Multiple Angle Control

Components

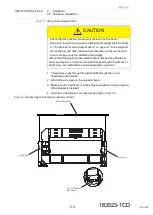

All Positioner tooling plates are fitted with a MotoMount™ flexible tool

mounting system as the tooling interface (see

2 "Tooling (Orbital) Axis “S” — Tooling Plate Multiple

).

Each AC servomotor incorporates a small Lithium-Ion “keep alive” battery

pack that maintains servo positioning data in memory, should the main

cables between the Positioner and Controller be disconnected. This

battery pack is part of each cable assembly (internal to the Positioner) that

connects each AC servomotor to its associated multi-pin plug on the

Positioner base. These battery packs have a very long life. However, if

they drop below a certain charge level, a “low battery” indication appears

on the Programming Pendant display screen.

Refer to

1 “Positioner Technical Specifications” on page 4-1

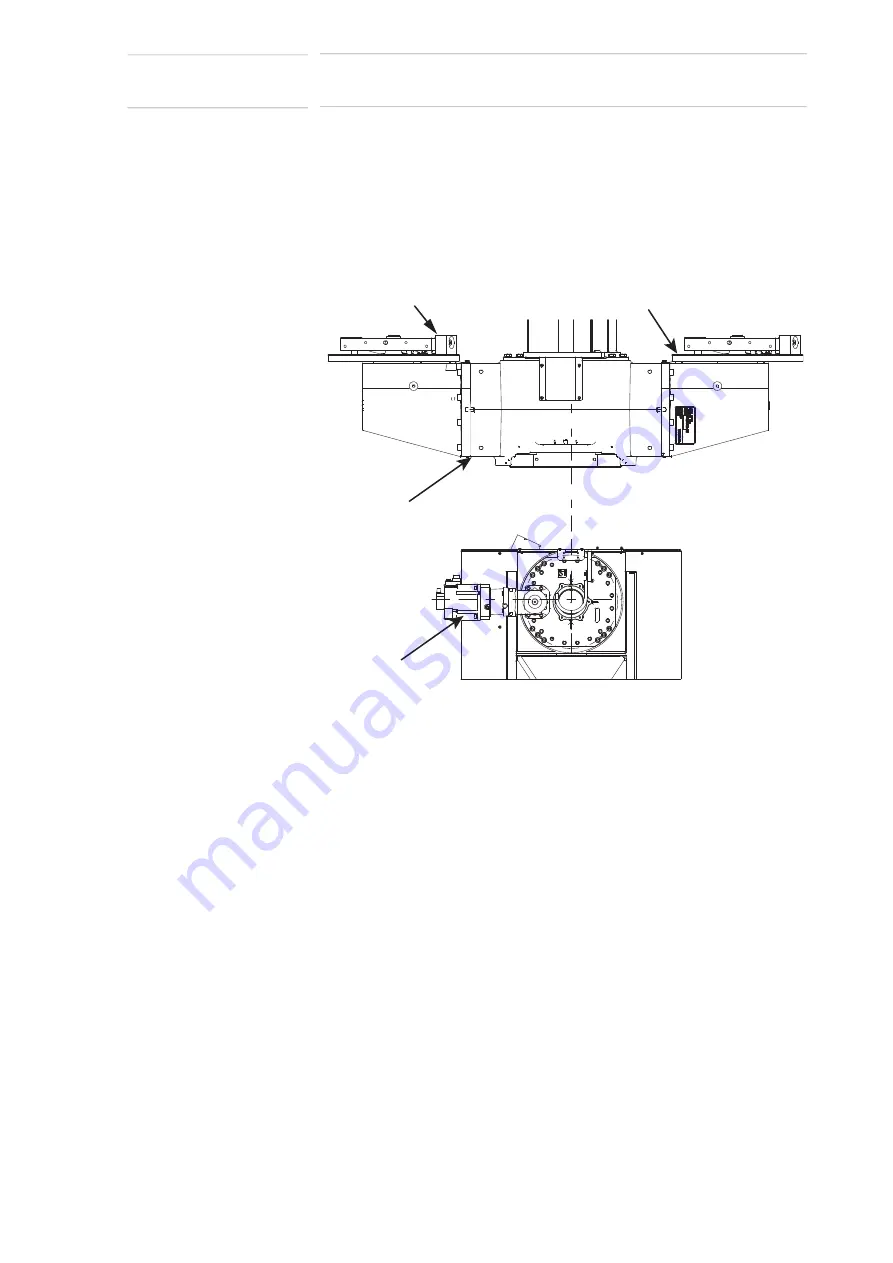

1.2.1 Positioner Configuration

The Positioner assembly main (sweep) axis AC servomotor and tooling

(orbital) axis AC servomotors are located on the headstock swingarm of

the Positioner. This configuration, along with other proprietary features,

gives the Positioner an exceptional Total Index Time (refer to

“Positioner Technical Specifications” on page 4-1

for a complete listing of

specifications).

SWINGARM ASSY

TOOLING DRIVE

TOOLING

PLATE (REF)

MOTOMOUNT

(REF)

SERVO

MOTOR

18 of 104