4.2 Settings for Common Basic Functions

4-15

4

Operation

4.2.7

Holding Brakes

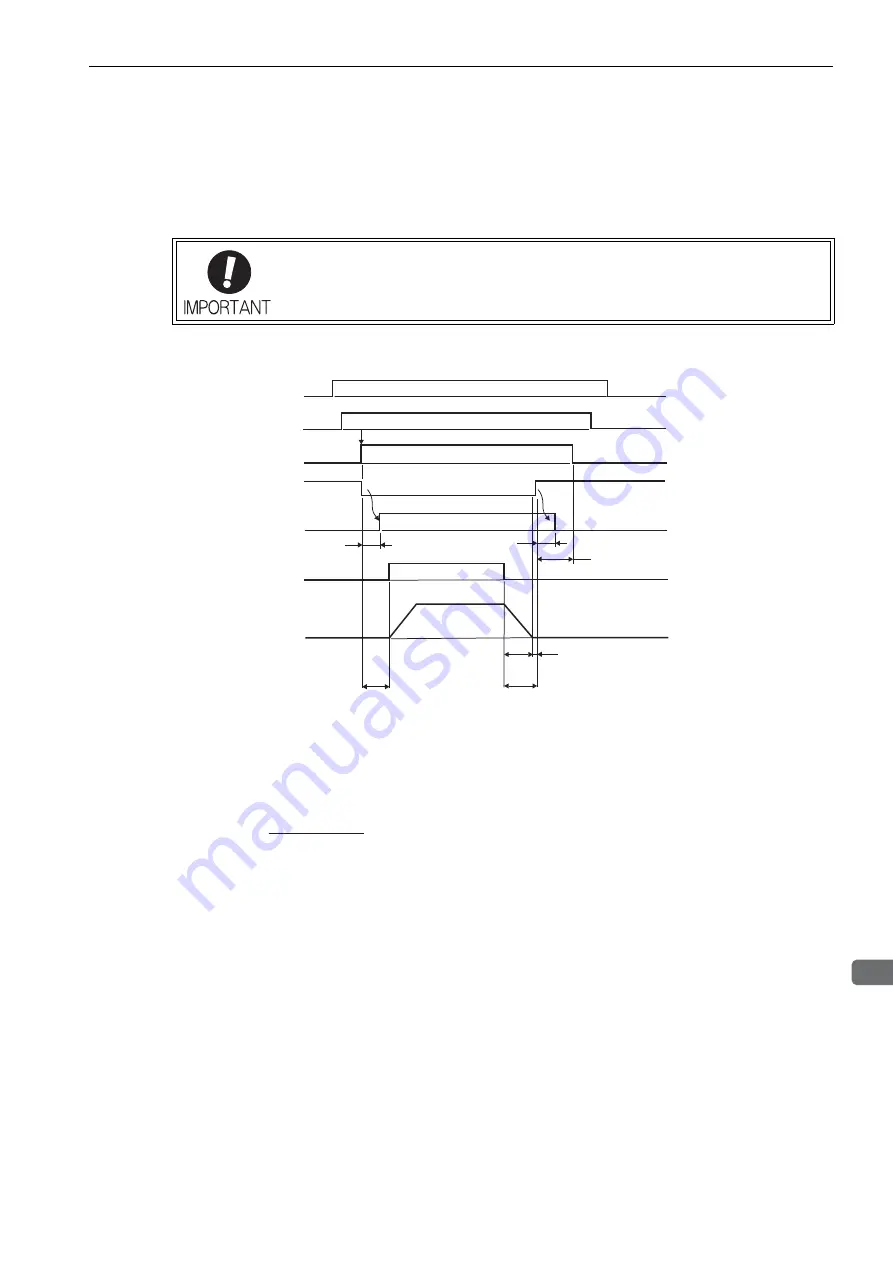

A holding brake is a brake used to hold the position of movable parts when the SERVOPACK is turned OFF

so that movable parts do not move due to their own weight or external forces. Separately provide a brake on

the machine side.

There is a delay in the braking operation. Set the following ON/OFF timing.

∗1.

The brake signal (/BK) turns ON at the timing the servo ON command is input.

∗2.

The operation delay time of the brake depends on the model. Set the ON/OFF timing according to the specifications

of the brake used.

∗3.

Allow a period of time required for the brake to be fully released before the speed reference is input after the brake

power supply is turned ON.

∗4.

The linear servomotor stop time is shown by t

d

. Use the following formula for the calculation of t

d

.

M

M

: Moving coil mass (kg)

J

L

: Load mass (kg)

V

M

: Motor speed (min

-1

)

F

D

: Motor deceleration force (N)

F

L

: Load force (Force from load side) (N)

∗5.

Make the settings so that the brake is applied after the linear servomotor comes to a stop. Usually, set t

d

+t

1

to 1 or 2

seconds.

∗6.

Use Pn506, Pn508, and Pn583 to set the timing of when the brake will be activated and when the linear servomotor

power will be turned OFF.

Do not keep the servo ON state with the brake applied.

OFF

OFF

OFF

OFF

Brake release

ON

ON

ON

ON

*1

*2

*4

*5

*6

*3

0V

*2

SERVOPACK main

power

SERVOPACK control

power

Servo ON command

Brake signal (/BK)

Brake contact part

(lining)

Speed reference

Motor speed

td

td+t1

t1

t

d

=

(F

D

+ F

L

)

(M

M

+ M

L

)

×

V

M