5.9 Compatible Adjustment Function

5-61

5

Adjustments

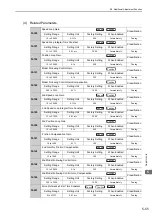

(1) Related Parameters

Select the conditions to switch modes (P or PI control switching) by using the following parameters.

Parameters to set the detection point

Mode switch functions according to the detection point are as follows.

Using the Force Reference Level to Switch Modes (Factory Setting)

With this setting, the speed loop is switched to P control when the value of force reference input exceeds the

force set in Pn10C.

The factory setting for the force reference detection point is 200% of the rated force.

Parameter

Mode Switch

Selection

Parameter

Containing

Detection Point

Setting

When

Enabled

Classification

Pn10B

n.

0

Uses a force reference level for detection point.

[Factory setting]

Pn10C

Immediately

Setup

n.

1

Uses a speed reference level for detection point.

Pn181

n.

2

Uses an acceleration level for detection point.

Pn182

n.

3

Uses an position error pulse level for detection

point.

Pn10F

n.

4

Does not use mode switch function.

−

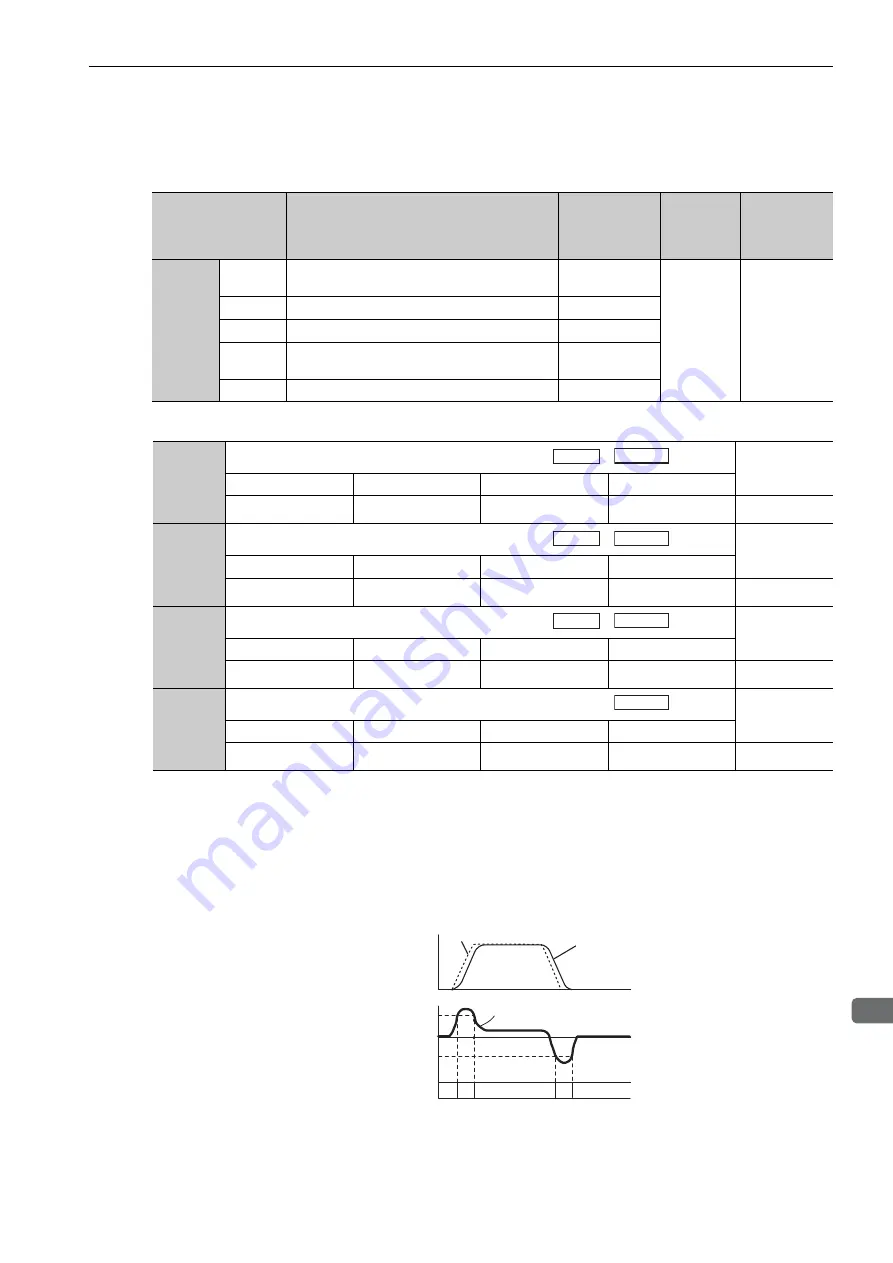

Pn10C

Mode Switch (Force Reference)

Classification

Setting Range

Setting Unit

Factory Setting

When Enabled

0 to 800

1%

200

Immediately

Tuning

Pn181

Mode Switch (Speed Reference)

Classification

Setting Range

Setting Unit

Factory Setting

When Enabled

0 to 10000

1 mm/s

0

Immediately

Tuning

Pn182

Mode Switch (Acceleration)

Classification

Setting Range

Setting Unit

Factory Setting

When Enabled

0 to 30000

1 mm/s

2

0

Immediately

Tuning

Pn10F

Mode Switch (Position Error Pulse)

Classification

Setting Range

Setting Unit

Factory Setting

When Enabled

0 to 10000

1 reference unit

0

Immediately

Tuning

Speed

Position

Speed

Position

Speed

Position

Position

Motor speed

Speed reference

Speed

+Pn10C

Force

reference

- Pn10C

Force reference

PI Control

PI Control

0

PI

P

P

Time