4 Operation

4.2.4 Electronic Gear

4-10

(3) Electronic Gear Ratio

Set the electric gear ratio using Pn20E and Pn210.

Use the following equation to calculate the electronic gear ratio.

Pn20E (Numerator B) and Pn210 (Denominator A) must be integers.

The set value must be within the range

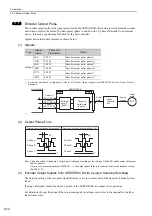

(4) Procedure for Setting the Electronic Gear Ratio

Electronic gear ratio set value differs depending on the machine specifications. Use the following procedure to

set the electronic gear ratio.

Pn20E

Electronic Gear Ratio (Numerator)

Classification

Setting Range

Setting Unit

Factory Setting

When Enabled

1 to 1073741824

(2

30

)

–

4

After restart

Setup

Pn210

Electronic Gear Ratio (Denominator)

Classification

Setting Range

Setting Unit

Factory Setting

When Enabled

1 to 1073741824

(2

30

)

–

1

After restart

Setup

Electronic gear ratio setting range:

0.001

≤

Electronic gear ratio (B/A)

≤

4000

If the electronic gear ratio is outside this range, a parameter setting error (A.040) will be

output.

Position

Position

Travel distance per position reference pulse (reference unit)

×

Number of divisions

B

A

Linear scale pitch

Pn20E

Pn210

=

=

Electronic gear ratio

=

0.001

B

A

4000.

≤

≤

Step

Operation

1

Check the scale pitch.

Check the scale pitch of linear scale used.

2

Determine the reference unit used.

Determine the reference unit from the host controller, considering the machine specifications and positioning

accuracy.

3

Calculate the electronic gear ratio.

Use the electronic gear ratio equation to calculate the ratio.

4

Set parameters.

Set parameters Pn20E and Pn210 using the calculated values.

5

Turn OFF the power supply and then ON again to validate the setting.