2.2 External Dimensions

2-8

2.2

External Dimensions

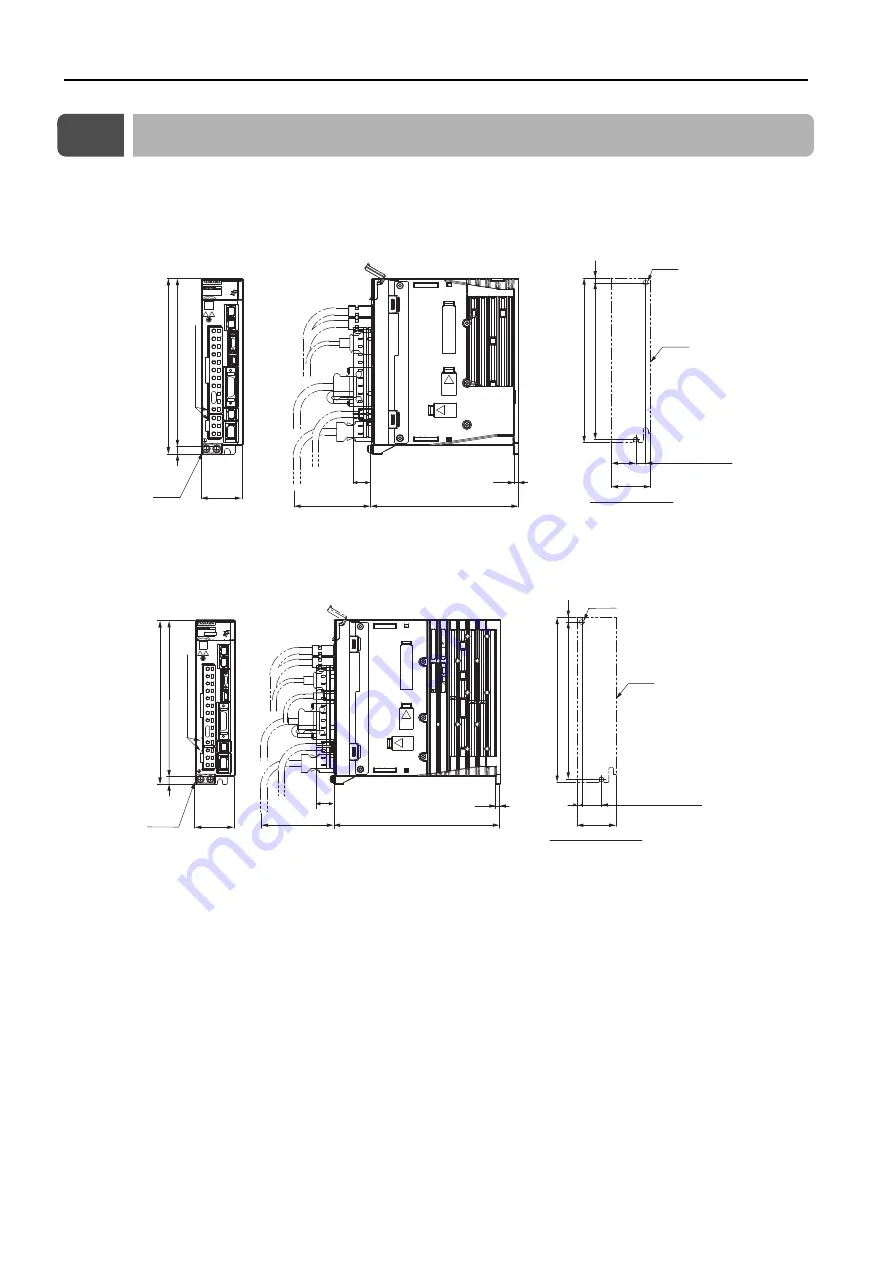

All SERVOPACKs that support the dynamic brake hardware option specifications are base-

mounted. The external dimensions are the same for all interfaces.

•

Three-Phase, 200 VAC: SGD7S-R70A, -R90A, and -1R6A

Note: There are no dynamic brake resistor terminals.

•

Three-Phase, 200 VAC: SGD7S-2R8A; Single-Phase, 100 VAC: SGD7S-R70F, -R90F, and

-2R1F

Note: There are no dynamic brake resistor terminals.

Two

s

et

s

of terminal

s

2

×

M4

160

168

8

40

Ground

terminal

s

2 × M4

(75)

140

18

(4)

168

160 ±0.5 (mounting pitch)

5

Exterior

10 ±0.5 (mounting pitch)

Mounting Hole Diagram

25

40

Unit: mm

Approx. ma

ss

: 0.9 kg

Two

s

et

s

of terminal

s

160

168

8

Ground

terminal

s

2 × M4

40

170

18

(4)

(75)

20

±

0.5 (mounting pitch)

168

160

±

0.5 (mounting pitch)

5

2

×

M4

Exterior

Mounting Hole Diagram

40

5

Unit: mm

Approx. ma

ss

: 1.1 kg