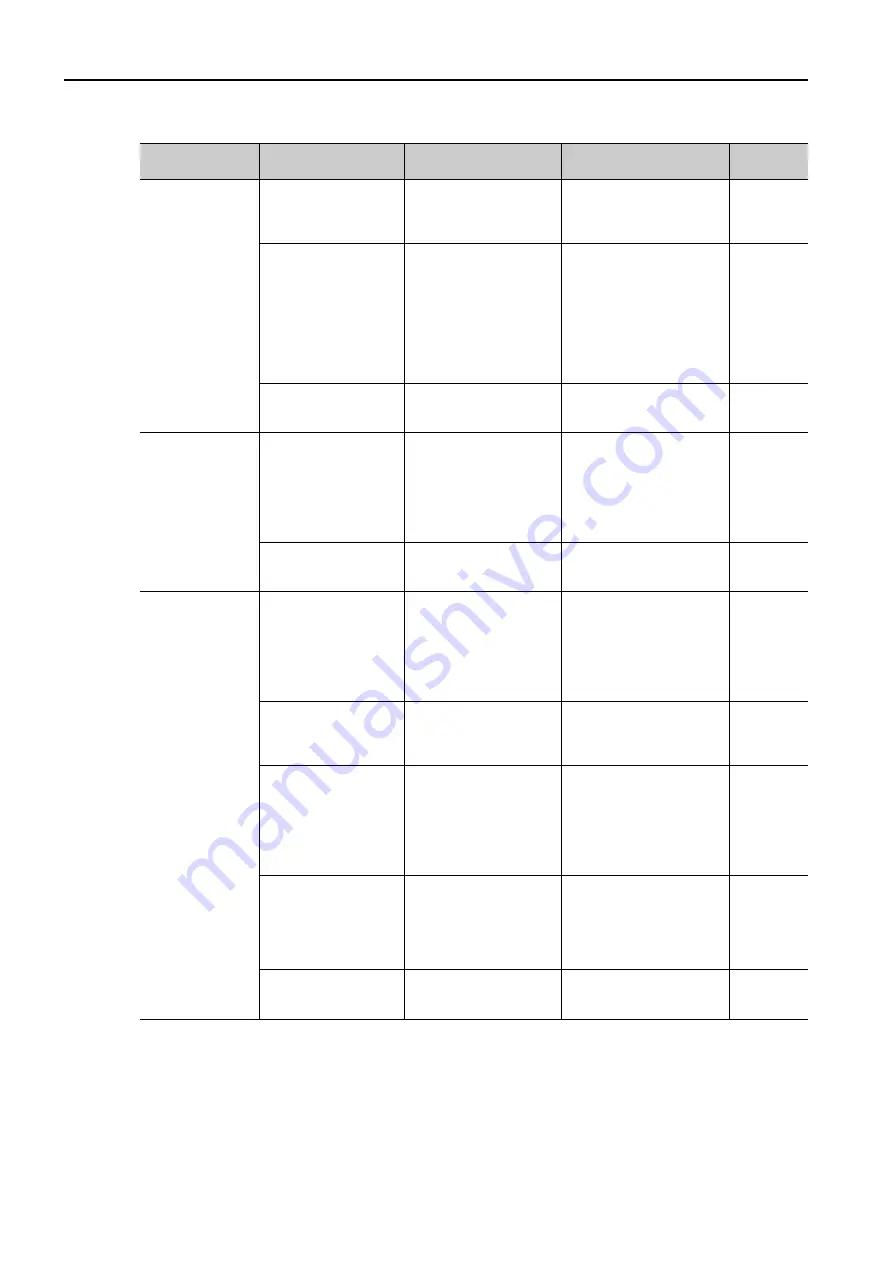

15.2 Alarm Displays

15.2.2 Troubleshooting Alarms

15-20

730 hex and

731 hex:

Dynamic Brake

Overload

(An excessive

power consump-

tion by the

dynamic brake

was detected.)

The Servomotor was

rotated by an external

force.

Check the operation

status.

Implement measures to

ensure that the motor will

not be rotated by an

external force.

–

When the Servomo-

tor was stopped with

the dynamic brake,

the rotational or linear

kinetic energy

exceeded the capac-

ity of the Dynamic

Brake Resistor.

Check the power con-

sumed by the DB resis-

tor to see how

frequently the DB is

being used.

Reconsider the following:

•

Reduce the Servomotor

command speed.

•

Decrease the moment

of inertia ratio or mass

ratio.

•

Reduce the frequency of

stopping with the

dynamic brake.

–

A failure occurred in

the SERVOPACK.

–

The SERVOPACK may be

faulty. Replace the SER-

VOPACK.

–

740 hex:

Inrush Current

Limiting Resistor

Overload

(The main circuit

power supply

was frequently

turned ON and

OFF.)

The allowable fre-

quency of the inrush

current limiting resis-

tor was exceeded

when the main circuit

power supply was

turned ON and OFF.

–

Reduce the frequency of

turning the main circuit

power supply ON and

OFF.

–

A failure occurred in

the SERVOPACK.

–

The SERVOPACK may be

faulty. Replace the SER-

VOPACK.

–

7A1 hex:

Internal Tempera-

ture Error 1

(Control Board

Temperature

Error)

The surrounding tem-

perature is too high.

Check the surrounding

temperature using a

thermostat. Or, check

the operating status

with the SERVOPACK

installation environment

monitor.

Decrease the surround-

ing temperature by

improving the SERVO-

PACK installation condi-

tions.

An overload alarm

was reset by turning

OFF the power sup-

ply too many times.

Check the alarm display

to see if there is an

overload alarm.

Change the method for

resetting the alarm.

–

There was an exces-

sive load or operation

was performed that

exceeded the regen-

erative processing

capacity.

Use the accumulated

load ratio to check the

load during operation,

and use the regenera-

tive load ratio to check

the regenerative pro-

cessing capacity.

Reconsider the load and

operating conditions.

–

The SERVOPACK

installation orientation

is not correct or there

is insufficient space

around the SERVO-

PACK.

Check the SERVOPACK

installation conditions.

Install the SERVOPACK

according to specifica-

tions.

A failure occurred in

the SERVOPACK.

–

The SERVOPACK may be

faulty. Replace the SER-

VOPACK.

–

Continued on next page.

Continued from previous page.

Alarm Code:

Alarm Name

Possible Cause

Confirmation

Correction

Reference